469610

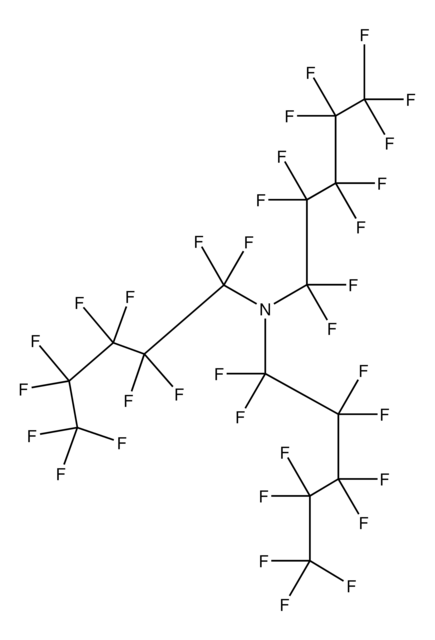

Poly[4,5-difluoro-2,2-bis(trifluoromethyl)-1,3-dioxole-co-tetrafluoroethylene]

dioxole 65 mol %

Synonym(s):

PTFE AF, PTFE AF 1600

Sign Into View Organizational & Contract Pricing

All Photos(1)

About This Item

Recommended Products

description

contact angle 104 ° with water

critical surface energy 15.7 dyn/cm

Quality Level

form

solid

composition

dioxole, 65 mol %

dielectric constant

1.934, 1 MHz (ASTM D 150)

hardness

103 (Rockwell, ASTM D 785, 23 °C)

transmittance

>95% (ASTM D 1003)

refractive index

n20/D 1.31

density

1.78 g/mL at 25 °C

Looking for similar products? Visit Product Comparison Guide

General description

Poly[4,5-difluoro-2,2-bis(trifluoromethyl)-1,3-dioxole-co-tetrafluoroethylene] (AF1600) is a fluorinated polymer that is formed by the copolymerization of 2,2-bis(trifluoromethyl)- 4,5-difluoro-1,3-dioxole and 1,1,2,2,- tetrafluoroethylene. It is an optically transparent photo-stable polymer with a high glass transition temperature (Tg), which can be used as a coating in electrochemical and electronic devices.

A tunable, polymeric, photonic material.

Application

AF1600 can form a hydrophobic coating on a silicon wafer that has a contact angle in the range of 115-120° which can be potentially used in agrochemical and printing applications. It may also form a self-assembled monolayer (SAM) on aluminum plates which can be used in the fabrication of water driven triboelectric nanogenerators (WTENGs).

Optoelectronic devices for optical clarity, low-refractive index coating for optical devices, protective coating for chemical resistance, release coating, and sight window for harsh chemical environments.

Physical form

Amorphous copolymer.

Storage Class Code

11 - Combustible Solids

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Personal Protective Equipment

dust mask type N95 (US), Eyeshields, Gloves

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Preparation of Superhydrophobic Teflon AF 1600 Sub-Micron Fibers and Yarns Using the Forcespinning? Technique.

Rane Y, et al.

Journal of Engineered Fibers and Fabrics, 8(4) (2013)

Wetting of hydrophobic substrates by pure surfactants at continuously increasing humidity

Ivanova NA, et al.

Colloids and Surfaces. A, Physicochemical and Engineering Aspects, 519(1), 71-77 (2017)

Theoretical study of micro/nano roughness effect on water-solid triboelectrification with experimental approach

Lee J and Hwang W

Nano Energy, 52(1), 315-322 (2018)

Properties of thin Teflon AF 2400 coatings deposited onto carbon fabric from solutions in supercritical carbon dioxide.

Kolomytkin DO, et al.

Polymer Science, Series A, 59(1), 42-52 (2017)

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service![Poly[4,5-difluoro-2,2-bis(trifluoromethyl)-1,3-dioxole-co-tetrafluoroethylene] dioxole 87 mol %](/deepweb/assets/sigmaaldrich/product/structures/951/320/21327fcd-4960-402d-8ae1-bf2e379cb2e2/640/21327fcd-4960-402d-8ae1-bf2e379cb2e2.png)