155721

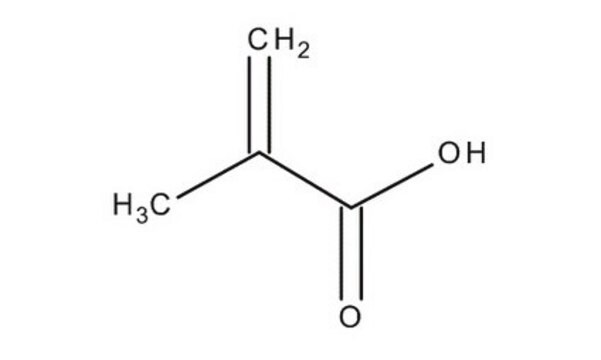

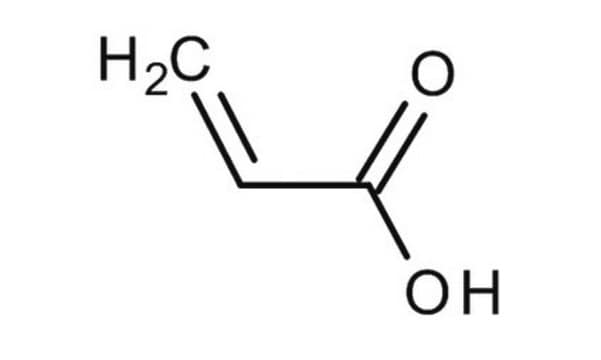

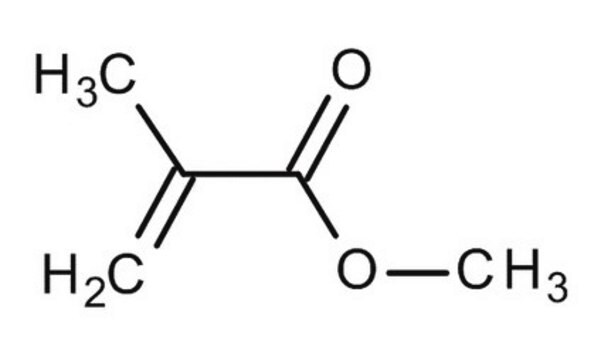

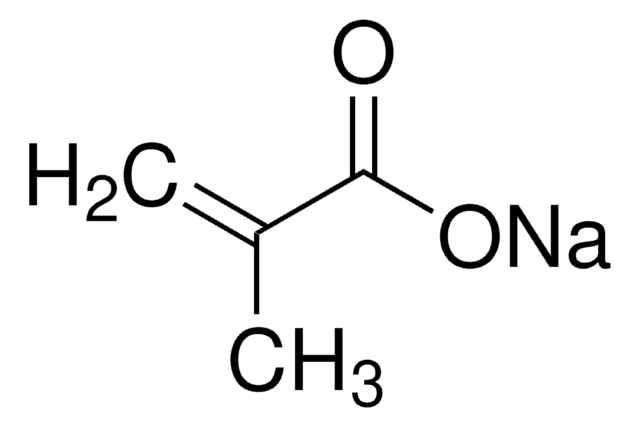

Methacrylic acid

contains 250 ppm MEHQ as inhibitor, 99%

Synonym(s):

2-Methacrylic acid, 2-Methylpropenoic acid

About This Item

Recommended Products

vapor density

>3 (vs air)

Quality Level

vapor pressure

1 mmHg ( 20 °C)

Assay

99%

form

liquid

autoignition temp.

752 °F

contains

250 ppm MEHQ as inhibitor

refractive index

n20/D 1.431 (lit.)

pH

2.0-2.2 (20 °C, 100 g/L)

bp

163 °C (lit.)

mp

12-16 °C (lit.)

density

1.015 g/mL at 25 °C (lit.)

SMILES string

C=C(C)C(O)=O

InChI

1S/C4H6O2/c1-3(2)4(5)6/h1H2,2H3,(H,5,6)

InChI key

CERQOIWHTDAKMF-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

General description

Application

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Acute Tox. 3 Dermal - Acute Tox. 4 Inhalation - Acute Tox. 4 Oral - Eye Dam. 1 - Skin Corr. 1A - STOT SE 3

Target Organs

Respiratory system

Storage Class Code

6.1C - Combustible acute toxic Cat.3 / toxic compounds or compounds which causing chronic effects

WGK

WGK 1

Flash Point(F)

152.6 °F - closed cup

Flash Point(C)

67 °C - closed cup

Personal Protective Equipment

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

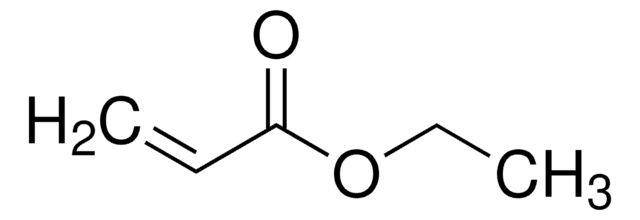

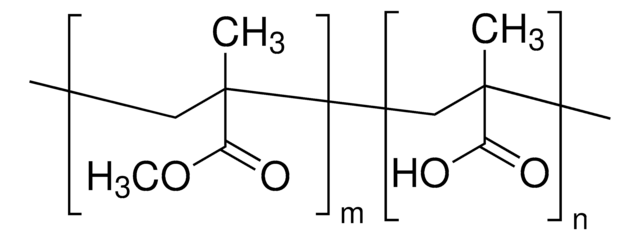

(RAFT) Polymerization

Composites

Articles

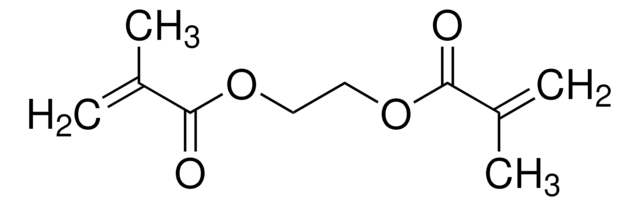

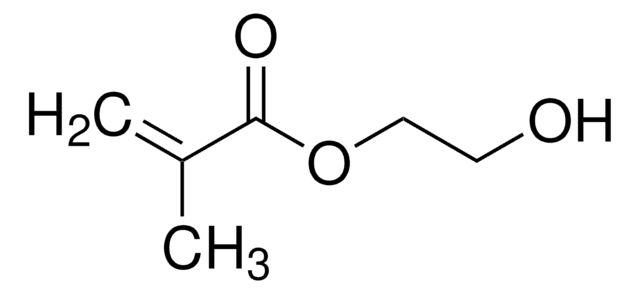

The manufacture of monomers for use in ophthalmic applications is driven by the need for higher purity, improved reliability of manufacturing supply, but ultimately by the need for the increased comfort, convenience, and safety of contact lens wearers. Daily wear contact lenses have the potential to fill this need for many customers; however, their widespread use is constrained by higher costs compared to weekly- or monthly-based lenses. New approaches that improve cost structure and result in higher quality raw materials are needed to help make contact lenses more affordable and accelerate growth of the contact lens market.

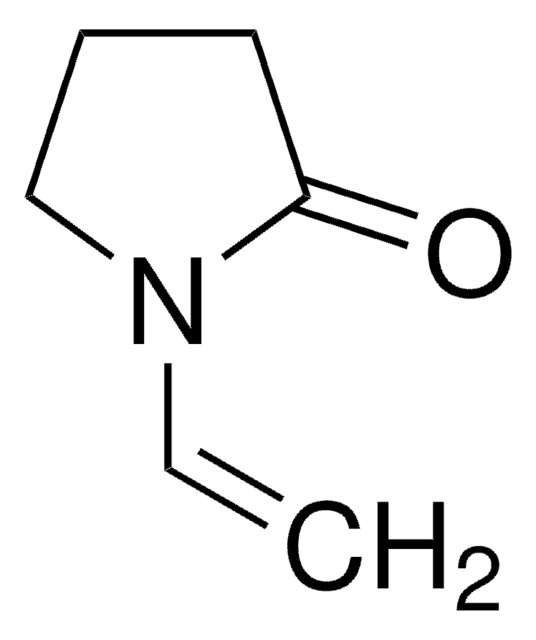

RAFT (Reversible Addition Fragmentation chain Transfer) polymerization is a reversible deactivation radical polymerization (RDRP) and one of the more versatile methods for providing living characteristics to radical polymerization.

By altering the physicochemical properties, smart or intelligent drug delivery systems can be designed to deliver therapeutic molecules on-demand. Learn more about the application of stimuli-responsive materials in drug delivery.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service