927651

TissueFab® bioink kit

(Gel)ma Fibrin (UV/365), low endotoxin

Synonym(s):

Fibrin, Fibrinogen, GelMA, Gelatin methacrylamide, Gelatin methacrylate, Gelatin methacryloyl, Thrombin

About This Item

Recommended Products

description

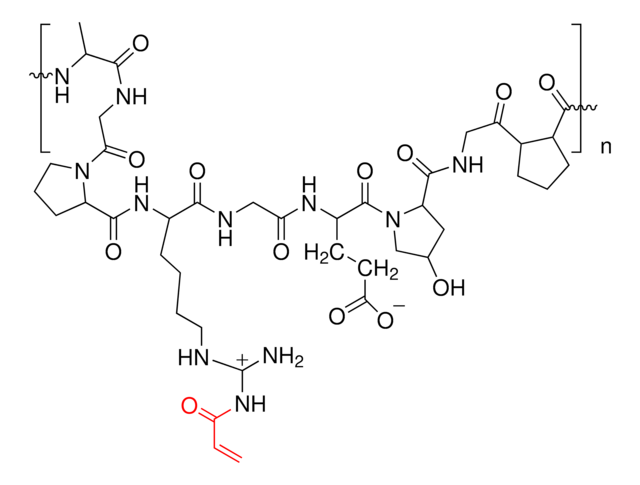

HNMR in D2O at 40°C

Quality Level

form

(Solid chunks, fibers or powder)

impurities

<10 CFU/g Bioburden (Fungal)

<10 CFU/g Bioburden (Total Aerobic)

<125 EU/g Endotoxin

color

white

storage temp.

2-8°C

Looking for similar products? Visit Product Comparison Guide

General description

Application

The protocol can be found under "More Documents" at the bottom of the page.

TissueFab® bioink kit- (Gel)ma Fibrin (UV/365), low endotoxin contains:

2- 500 mg lyophilized ink components

1- lyophilized thrombin powder

1- 10 ml HEPES buffer.

Features and Benefits

Low Endotoxin, low bioburden: Endotoxins have been demonstrated negatively impact cellular growth, morphology, differentiation, inflammation and protein expression. Bioburden is defined as the number of contaminated organisms found in a given amount of material. We test each lot for endotoxins as well as total bioburden (aerobic and fungal) to minimize unwanted interactions. For more information: https://www.sigmaaldrich.com/US/en/technical-documents/technical-article/microbiological-testing/pyrogen-testing/what-is-endotoxin

Legal Information

related product

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Eye Irrit. 2 - Resp. Sens. 1 - Skin Irrit. 2 - STOT SE 3

Target Organs

Respiratory system

Storage Class Code

10 - Combustible liquids

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Sorry, we don't have COAs for this product available online at this time.

If you need assistance, please contact Customer Support.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service