Comparison of Granulated and Powdered Dehydrated Culture Media

Dehydrated culture media (DCM) to grow microorganisms in broth or on agar plates are available on the market in both powdered or granulated forms. Though their chemical composition is identical, they differ with respect to their particle sizes. Traditional powdered media consist of tiny particles sized less than 100 µm , while the granules are visible with the naked eye, reaching 1,000 µm or more. Both types of dehydrated culture media offer identical growth promotion performance. But how else do they compare?

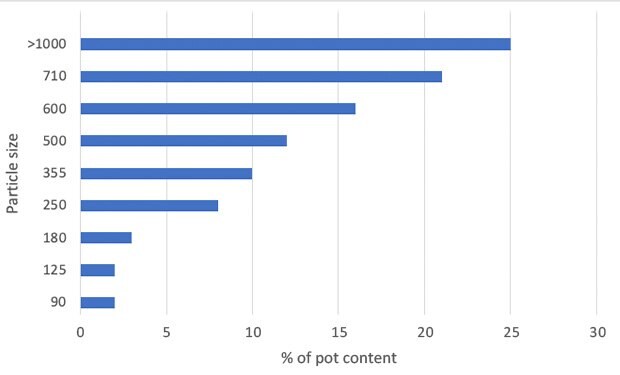

Figure 1.Granulated (left) and powdered (right) microbial culture media.

FROM POWDERED MEDIA TO GRANULES

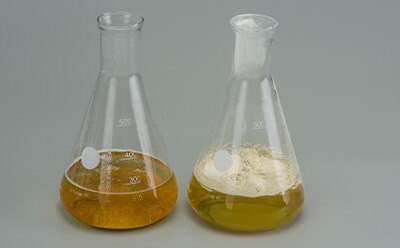

Dehydrated culture media granules are basically firm but loosely bound powdered media. To produce them, the powder mixture is subjected to a water- and additive-free roller compaction process known as granulation. This process, which is purely mechanical and thus also suitable where components are heat-sensitive, leads the powdered media to clump and form granules of different sizes (Fig. 2) that dissolve rapidly when water is added. During transportation of the product to the customer, a small proportion of the granules fragment into smaller ones, and abrasion can lead to powder settling at or near the bottom of the container. Studies have shown that these powder residuals are identically composed to the granules and offer the same growth promoting performance.1

Figure 2.Example of the particle frequency in a container of agar medium.

Selective ingredients can be incorporated into granules just as well as into powdered media, freeing labs of the need to purchase and store expensive supplements.

THE ADVANTAGES OF GRANULATED CULTURE MEDIA

In the 1950s we pioneered the granulation of powdered dehydrated culture media. Since then our granulated media, offered under the GranuCult® brand with the addition “plus” or “prime” to indicate the QC level, have penetrated the market due to their many advantages over powdered media. Although granulation is an additional step in the manufacturing process, the extra costs have not posed an obstacle because the media are produced on an industrial scale, keeping the overheads low. Most of our dehydrated culture media to prepare agar plates or broths for microbiological quality control testing of pharmaceuticals, food, and beverages are now available in the granulated form.

Granulated media offer advantages over powdered media with regard to:

- Safety

- Accuracy

- Speed

- Convenience

- Shelf life

It is worthwhile looking more closely into why this is the case.

Safety: Better Protection for Lab Staff

While powdered media are weighed and transferred into flasks, fine particles drift as hardly visible clouds through the air and across the working area, causing laboratory personnel to inhale them. Because many culture media contain hazardous or toxic substances (Table 1 for examples), this is a health concern. Bile salts, for example, constituents of Violet Red Bile Glucose Agar, irritate the mucosa and trigger coughing. Powdered media particles also contaminate the skin, eyes, and ears, where they can lead to allergic reactions. Granulated dehydrated culture media, on the other hand, stir up much less powder during handling. Consequently, the danger of inhaling hazardous or toxic substances is significantly lower, and this helps to maintain a safer, cleaner working environment.

Accuracy: No Separation or Weighing Issues

Granulation preserves the homogeneity of culture media by capturing its original component distribution in each granule and by preventing those components from settling into separate layers. This eliminates the need for tumbling to redistribute components, as is sometimes required with powdered media. In addition, handling and weighing powdered media can lead to dust settling on and around balances, bringing with it not only the need for extra cleaning, but also the risk of inaccurate weighing results.

Figure 3.Dust formation of granulated (left) and powdered (right) culture medium after filling in an Erlenmeyer flask.

Speed: Granules Dissolve Faster

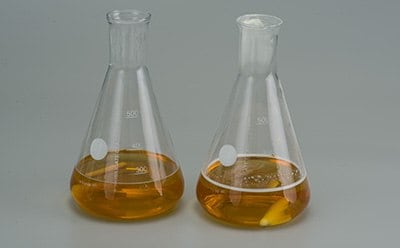

Weighing and preparing granulated media is easy thanks to its free-flowing properties, and this takes less time than with powdered media. After adding water the granules dissolve easily within minutes (except agar and gelatin, of course). This is because water coats and penetrates the granules much quicker than it does fine powders. Powders tend to float on the water until forced into solution, while granules sink into the water naturally, beginning to dissolve as soon as they are coated with water.

Figure 4.Dissolving of granulated (left) and powdered (right) culture media in water.

Convenience: No Clumping, No Sticking

Powdered dehydrated culture media tends to clump and stick to the bottom of culture media flasks. Such clumps are sometimes difficult to dissolve. Powdered media also likes to stick to a flask’s neck, making cleaning necessary as undissolved media can caramelize upon subsequent heating. Granulated media, on the other hand, possesses better flow properties, making it easier to weigh out and transfer from the weighing booth to a flask. It doesn’t stick to the neck of the flask or clump within it. Swirling the flask gently is enough to dissolve the media’s components.

Figure 5.Solubility of granulated (left) and powdered (right) culture media after stirring.

Stability: Longer Shelf Life

Most of our granulated dehydrated culture media have a shelf life of 5 years, much longer than some commercial powdered media’s 3-year shelf life. Granulated media have a lower water content when they are produced, and the granules themselves are less affected by ambient moisture when containers are opened and closed. There is less clumping even under warm or humid conditions, ensuring a stable product over its entire shelf life. Longer shelf lives generally mean that less media have to be thrown away as a consequence of product expiry, which saves costs over time.

SUMMARY

While granulated dehydrated culture media possess the same growth promotion properties as powdered media, they are at a clear advantage with regard to safety, accuracy, speed, convenience, and stability. Because the purely mechanical process of granulating powdered media involves neither adding substances nor causing damage to heat-sensitive ingredients, it has been possible to apply it to the vast majority of culture media used in microbiological quality control testing of food, beverages, and pharmaceuticals.

References

Para seguir leyendo, inicie sesión o cree una cuenta.

¿No tiene una cuenta?