463310

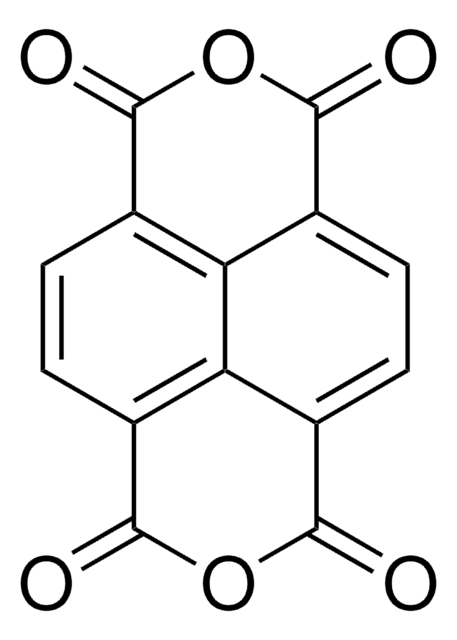

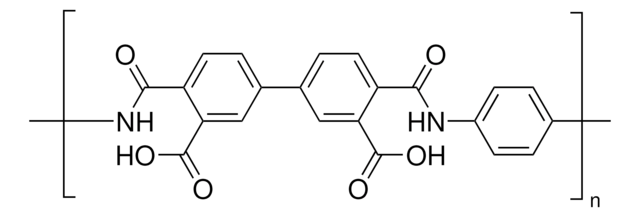

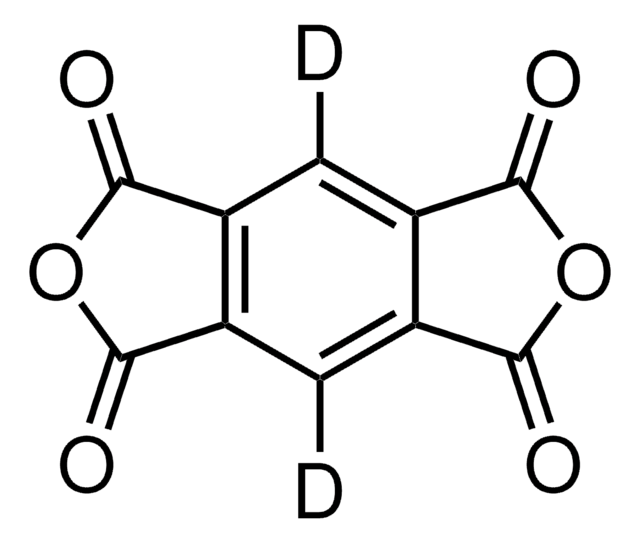

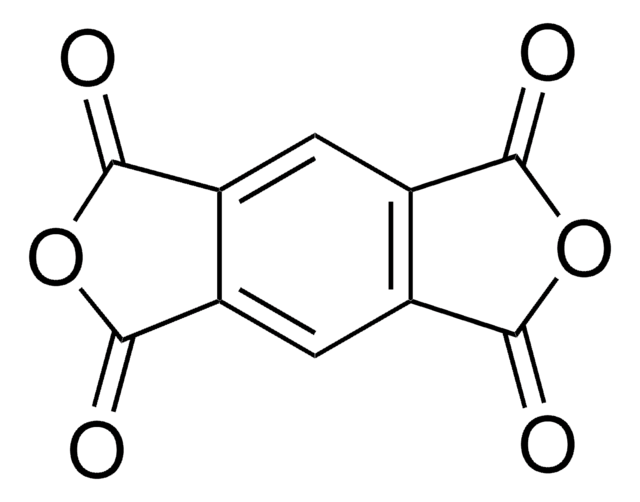

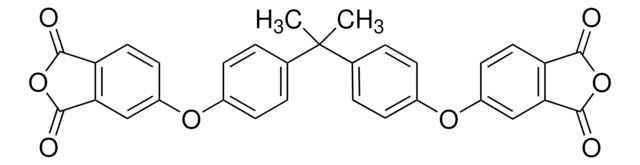

3,3′,4,4′-Biphenyltetracarboxylic dianhydride

97%

Synonym(s):

s-BPDA

Sign Into View Organizational & Contract Pricing

All Photos(1)

About This Item

Empirical Formula (Hill Notation):

C16H6O6

CAS Number:

Molecular Weight:

294.22

EC Number:

MDL number:

UNSPSC Code:

12162002

PubChem Substance ID:

NACRES:

NA.23

Recommended Products

Assay

97%

mp

299-305 °C (lit.)

SMILES string

O=C1OC(=O)c2cc(ccc12)-c3ccc4C(=O)OC(=O)c4c3

InChI

1S/C16H6O6/c17-13-9-3-1-7(5-11(9)15(19)21-13)8-2-4-10-12(6-8)16(20)22-14(10)18/h1-6H

InChI key

WKDNYTOXBCRNPV-UHFFFAOYSA-N

Related Categories

General description

3,3′,4,4′-Biphenyltetracarboxylic dianhydride (s-BPDA) is a rigid symmetric polyamide with a diamine having a long distance between amine groups and reactive endgaps.

Application

s-BPDA can be used in the synthesis of high molecular weight aromatic polyamide fibers. It can also be used in the formation of hybrid nanocomposite films.

Signal Word

Warning

Hazard Statements

Precautionary Statements

Hazard Classifications

Eye Irrit. 2 - Skin Irrit. 2 - STOT SE 3

Target Organs

Respiratory system

Storage Class Code

11 - Combustible Solids

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Personal Protective Equipment

dust mask type N95 (US), Eyeshields, Gloves

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

High thermal stable thermoplastic-thermosetting polyimide film by use of asymmetric dianhydride (a-BPDA)

Sasaki T, et al.

Polymer, 46(18), 6968-6975 (2005)

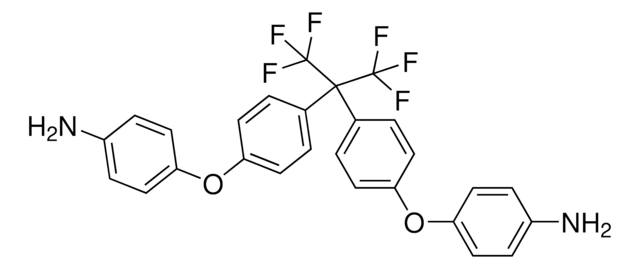

High performance aromatic polyimide fibers, 3. A polyimide synthesized from 3, 3?, 4, 4?-biphenyltetracarboxylic dianhydride and 2, 2?-dimethyl-4, 4?-diaminobiphenyl

Eashoo M, et al.

Macromolecular Chemistry and Physics, 195(6), 2207-2225 (1994)

Microstructure and properties of 3, 3?, 4, 4?-biphenyltetracarboxylic dianhydride (BPDA)-p-phenylene diamine (PDA) polyimide/poly (vinylsilsesquioxane) hybrid nanocomposite films

Wahab MA, et al.

Journal of Polymer Science Part A: Polymer Chemistry, 42(20), 5189-5199 (2004)

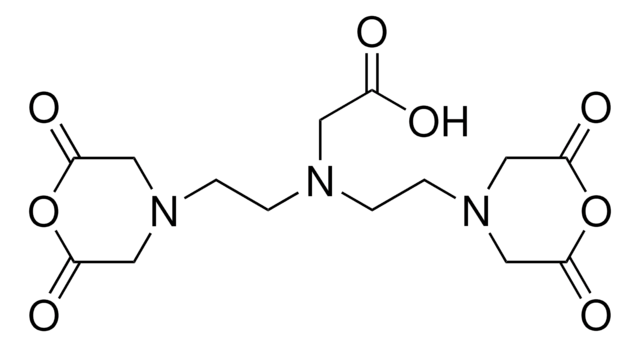

Mengjie Zhang et al.

Journal of colloid and interface science, 547, 136-144 (2019-04-06)

The aim of this study is to prepare a fibrous membrane scaffold that possesses a frogspawn structure for high-efficiency oil-water separation. Polyamic acid was first electrospun onto a rotating wheel-collector to obtain the fibrous membrane. Subsequently, post-processing by immersion in

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service

![Bicyclo[2.2.2]oct-7-ene-2,3,5,6-tetracarboxylic dianhydride 99%](/deepweb/assets/sigmaaldrich/product/structures/418/038/9edd3533-0f32-442c-8a1f-4e154e65c3b5/640/9edd3533-0f32-442c-8a1f-4e154e65c3b5.png)