347078

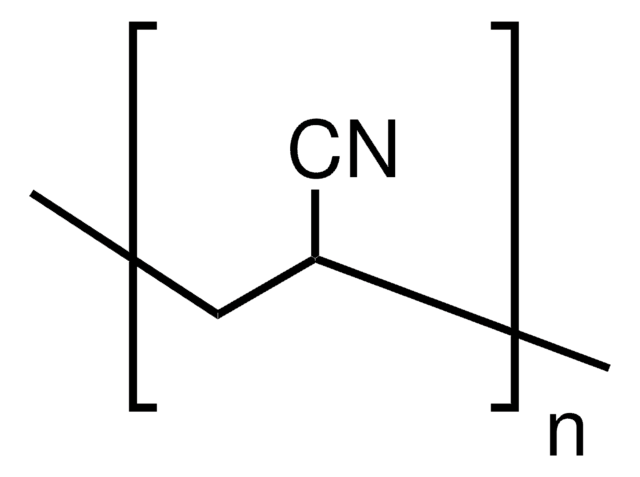

Poly(vinylidene fluoride)

average Mw ~530,000, pellets

Synonym(s):

PVDF

Sign Into View Organizational & Contract Pricing

All Photos(2)

About This Item

Linear Formula:

(CH2CF2)n

CAS Number:

MDL number:

UNSPSC Code:

12162002

PubChem Substance ID:

NACRES:

NA.23

Recommended Products

vapor pressure

15 mmHg ( 32 °C)

form

pellets

mol wt

average Mw ~530,000

SMILES string

FC(F)=C

InChI

1S/C2H2F2/c1-2(3)4/h1H2

InChI key

BQCIDUSAKPWEOX-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

Related Categories

Application

- A critical analysis of the α, β and γ phases in poly (vinylidene fluoride) using FTIR: This study provides detailed insights into the different crystalline phases of PVDF, which are crucial for applications in sensors and actuators (Cai et al., 2017).

- Properties and applications of the β phase poly (vinylidene fluoride): This research explores the unique properties of the β phase of PVDF, widely used for its piezoelectric and ferroelectric properties, relevant in various technological applications (Ruan et al., 2018).

- Ultrahigh β-phase content poly (vinylidene fluoride) with relaxor-like ferroelectricity for high energy density capacitors: This article discusses the potential of high β-phase PVDF in energy storage applications, which could interest material scientists focusing on energy solutions (Meng et al., 2019).

- Multiscale-structuring of polyvinylidene fluoride for energy harvesting: This study investigates how different scales of structural modification affect the energy harvesting capabilities of PVDF, important for both material science and sustainable energy research (Wan & Bowen, 2017).

- Recent advances in poly (vinylidene fluoride) and its copolymers for lithium-ion battery separators: This review highlights the applications of PVDF in the development of lithium-ion battery separators, essential for advancing energy storage technologies (Barbosa et al., 2018).

Storage Class Code

11 - Combustible Solids

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Personal Protective Equipment

dust mask type N95 (US), Eyeshields, Gloves

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Yu-Jen Hsu et al.

The Journal of the Acoustical Society of America, 132(6), 3826-3831 (2012-12-13)

A tone analyzer is demonstrated using a distributed resonator architecture on a tensioned piezoelectric polyvinyledene diuoride (PVDF) sheet. This sheet is used as both the resonator and detection element. Two architectures are demonstrated; one uses distributed, directly addressed elements as

S V Ivanov et al.

Klinichna khirurhiia, (7)(7), 37-41 (2012-10-05)

The results of experimental and clinical studies for the comparative evaluation of implants used in herniology of polytetrafluoroethylene (PTFE) and polyvinylidene fluoride (PVDF) are presented. Experimental investigations conducted on 200 mice, which in the anterior abdominal wall mesh prosthesis implanted.

X S Yi et al.

Water science and technology : a journal of the International Association on Water Pollution Research, 67(3), 477-484 (2012-12-04)

In the present study, nano-sized TiO(2)/Al(2)O(3) modified polyvinylidene fluoride (PVDF) membranes (MM) were fabricated and then utilized for oil/water emulsion separation. The results showed that, compared with PVDF membrane (OM), the contact angle of MM decreased and hydrophilicity increased. The

Adhikara Resosudarmo et al.

Water research, 47(2), 911-921 (2012-12-12)

Organic fouling remains a significant challenge in the application of ultrafiltration (UF) pretreatment systems in the desalination industry. In this study, the fouling potential of organic materials in seawater was investigated using model seawater solution containing humic acid and alginate.

Vincent S D Voet et al.

Nanoscale, 5(1), 184-192 (2012-11-10)

The fabrication of nanoporous poly(vinylidene fluoride) (PVDF) and PVDF/nickel nanocomposites from semicrystalline block copolymer precursors is reported. Polystyrene-block-poly(vinylidene fluoride)-block-polystyrene (PS-b-PVDF-b-PS) is prepared through functional benzoyl peroxide initiated polymerization of VDF, followed by atom transfer radical polymerization (ATRP) of styrene. The

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service