FIPMS176

Back-gated OFET Substrate

n-doped silicon wafer with 230 nm SiO2 gate-insulator, chips (diced)

Sign Into View Organizational & Contract Pricing

All Photos(1)

About This Item

UNSPSC Code:

43211915

NACRES:

NA.23

Recommended Products

form

chips (diameter 200 mm)

chips (diced)

packaging

pack of 1 (wafer of 112 diced chips)

Related Categories

General description

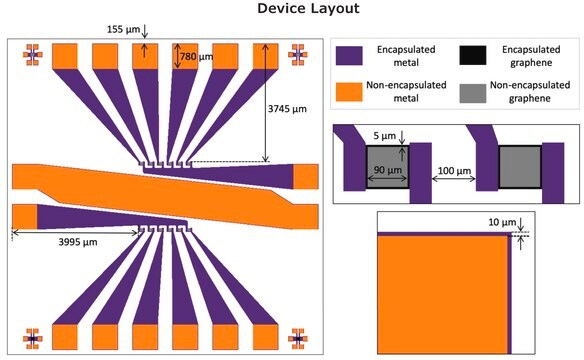

Substrate: 200 mm wafer according to semiconductor standard (used for bottom-gate)

Layer structure:

Layer structure:

- Gate: n-doped silicon (doping at wafer surface: n~3x1017/ cm3)

- Gate oxide: 230 nm ± 10 nm SiO2 (thermal oxidation)

- Drain/source:none

- Protection: resist AR PC 5000/3.1 (soluble in AZ-Thinner or acetone)

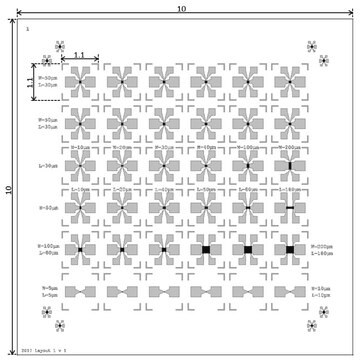

- Layout: bare oxide but diced

- Chip size: 15 x 15 mm2

- No. of chips: 112 per wafer

Application

Back-gated OFET Substrate (organic field-effect transistor) can be used in the fabrication of chemical sensors for potential usage in pH sensing and detection of immunoassays. It can also be used in the fabrication of biosensors by coating the sheets of the FET with a specific antibody for the detection of SARS-CoV-2. FET based biosensors can be potentially used in clinical diagnosis, point of care testing, and on-site detection.

For material scientists in the field of organic semiconductors, it is critically important to have standardized device architecture for material analysis.

These back-gated organic filed-effect transistor (OFET) substrates were fabricated inside the cleanroom, and source and drain electrodes can be deposited either prior or after the deposition of an organic semiconductor material, giving versatility for the choice of source/drain materials and satisfy different preferred device architectures.

When an organic semiconductor layer is deposited on such a substrate, the bulk Si acts as gate electrode and controls the channel current between the post-deposited source and drain electrodes on the top. A suitably doped Si-SiO2 interface in CMOS quality guarantees a reproducible gate contact.

These back-gated organic filed-effect transistor (OFET) substrates were fabricated inside the cleanroom, and source and drain electrodes can be deposited either prior or after the deposition of an organic semiconductor material, giving versatility for the choice of source/drain materials and satisfy different preferred device architectures.

When an organic semiconductor layer is deposited on such a substrate, the bulk Si acts as gate electrode and controls the channel current between the post-deposited source and drain electrodes on the top. A suitably doped Si-SiO2 interface in CMOS quality guarantees a reproducible gate contact.

Packaging

diced wafer on foil with air tight packaging

Preparation Note

Recommendation for resist removal:

To guarantee a complete cleaning of the wafer / chip surface from resist residuals, please rinse by acetone and then dry the material immediately by nitrogen (compressed air).

Recommendation for material characterization:

If gate currents appear during the characterization of the field effect transistors, considerable variations could occur at the extraction of the carrier mobility. Therefore it is necessary to check the leakage currents over the reverse side (over the chip edges) of the OFET-substrates.

To guarantee a complete cleaning of the wafer / chip surface from resist residuals, please rinse by acetone and then dry the material immediately by nitrogen (compressed air).

Recommendation for material characterization:

If gate currents appear during the characterization of the field effect transistors, considerable variations could occur at the extraction of the carrier mobility. Therefore it is necessary to check the leakage currents over the reverse side (over the chip edges) of the OFET-substrates.

Storage and Stability

Store the wafers at a cool and dark place and protect them against sun.Resist layer was applied to prevent damage from scratches. Expiration date is the recommended period for resist removal only. After resist removal, the substrate remains functional and does not expire.

Legal Information

Product of Fraunhofer IPMS

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Lot/Batch Number

Sorry, we don't have COAs for this product available online at this time.

If you need assistance, please contact Customer Support.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

The impact of biosensing in a pandemic outbreak: COVID-19

Morales-Narvaez E and Dincer C

Biosensors And Bioelectronics, 14(4), 112274-112274 (2020)

Polymer composite-based OFET sensor with improved sensitivity towards nitro based explosive vapors

Dudhe RS, et al.

Sensors and Actuators B, Chemical, 148(1), 158-165 (2010)

Rapid detection of COVID-19 causative virus (SARS-CoV-2) in human nasopharyngeal swab specimens using field-effect transistor-based biosensor

Seo G, et al.

ACS Nano, 14(4), 5135-5142 (2020)

Random CNT network and regioregular poly (3-hexylthiophen) FETs for pH sensing applications: A comparison

Munzer AM, et al.

Biochim. Biophys. Acta Gen. Subj., 1830(9), 4353-4358 (2013)

Articles

Professor Tokito and Professor Takeda share their new materials, device architecture design principles, and performance optimization protocols for printed and solution-processed, low-cost, highly flexible, organic electronic devices.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service