663492

Nafion™ perfluorinated resin solution

20 wt. % in lower aliphatic alcohols and water, contains 34% water

Synonym(s):

D-2020

About This Item

Recommended Products

contains

34% water

greener alternative product characteristics

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

concentration

20 wt. % in lower aliphatic alcohols and water

density

1.02 g/mL at 25 °C

greener alternative category

InChI

1S/C7HF13O5S.C2F4/c8-1(9)2(10)24-5(15,16)3(11,4(12,13)14)25-6(17,18)7(19,20)26(21,22)23;3-1(4)2(5)6/h(H,21,22,23);

InChI key

FOYUGSIADQEOEK-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

General description

Application

Legal Information

related product

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Eye Dam. 1 - Flam. Liq. 2 - Skin Irrit. 2 - STOT SE 3

Target Organs

Central nervous system

Storage Class Code

3 - Flammable liquids

WGK

WGK 2

Flash Point(F)

55.4 °F

Flash Point(C)

13 °C

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Articles

Fuel cells have the potential to reduce the nation’s energy use through increased energy conversion efficiency and dependence on imported petroleum by the use of hydrogen from renewable resources.

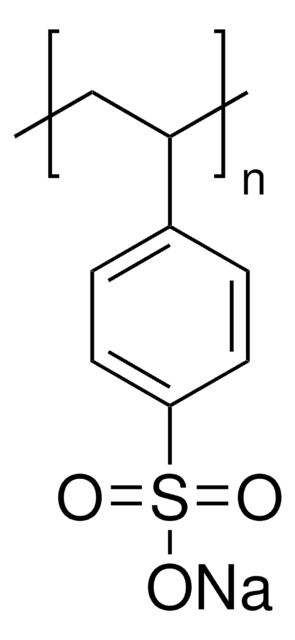

Proton exchange membrane (PEM) fuel cells operate at relatively low temperatures and are composed of two electrodes and a conductive elecrolyte.

Advances in the electrochemical conversion of water to and from hydrogen and oxygen have principally been achieved through the development of new materials and by understanding the mechanisms of the degradation of proton exchange membrane fuel cells (PEMFC) during operation.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service