918571

3D Printable Yttria-stabilized Zirconium(IV) Oxide Ink

Synonym(s):

3D printable ceramic ink, 3Y-ZrO2 ink, YSZ ink, Yttria stabilized zirconia ink, Yttrium stabilized zirconium oxide ink

About This Item

Recommended Products

description

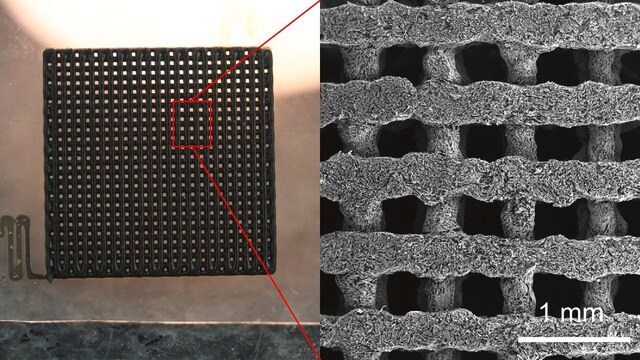

Printing methods compatible with: Direct-Ink-Writing 3D printing

Quality Level

form

paste

greener alternative product characteristics

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

concentration

70 wt. % (Yttria stabilized zirconia)

color

white

particle size

120 nm

viscosity

2-25 Pa.s (25 °C at shear rate of 100 s-1)

greener alternative category

storage temp.

2-8°C

General description

Application

Caution

- Store in an airtight sealed container in refrigerator.

- Avoid exposure to heat.

- Add the thermal initiator (product No.479896) to 0.3wt% of the total 3Y-ZrO2/PEGDA ink mass, and mix well before usage.

Preparation Note

Direct-Ink-Writing (DIW) Notes:

- Syringe Nozzle sizes ranging from 250 μm − 800 μm can be used.

- Initial pressure for DIW printing ranges from 12-18 psi, depending on nozzle diameter used.

Post Processing of DIW printed parts:

- Curing @ 110°C for 12-16 hours.

- Sintering using the following sequence:

Ramp to 300°C @ 1°C/min. Hold for 4 hours.

Ramp to 400°C @ 1°C/min. Hold for 2 hours.

Ramp to 800°C @ 2°C/min. Hold for 4 hours.

Ramp to 1090°C @ 2°C/min. Hold for 15 hours.

Ramp down to 50°C @ 2°C/min.

Storage and Stability

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Eye Dam. 1 - Skin Irrit. 2 - Skin Sens. 1 - STOT SE 3

Target Organs

Respiratory system

Storage Class Code

10 - Combustible liquids

WGK

WGK 3

Choose from one of the most recent versions:

Certificates of Analysis (COA)

It looks like we've run into a problem, but you can still download Certificates of Analysis from our Documents section.

If you need assistance, please contact Customer Support.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service