701963

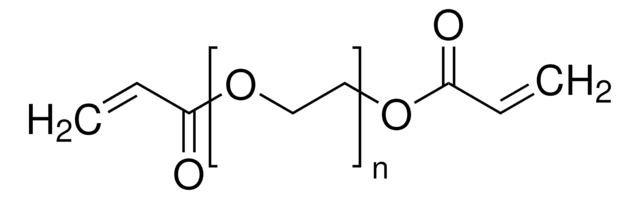

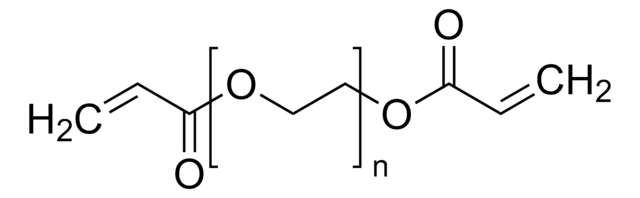

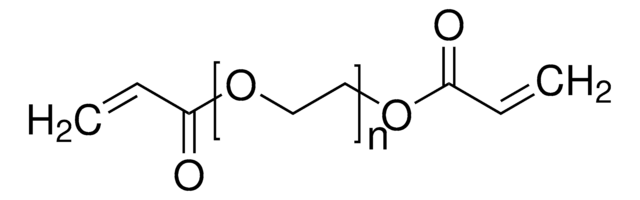

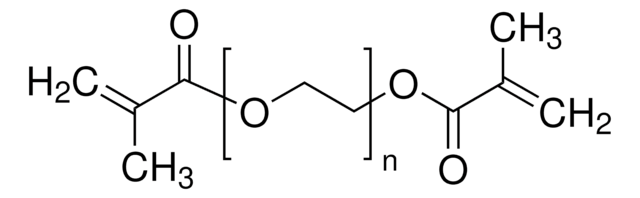

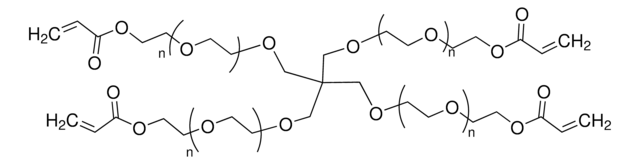

Poly(ethylene glycol) diacrylate

average Mn 6,000, acrylate, ≤1,500 ppm MEHQ as inhibitor

Synonym(s):

Polyethylene glycol, PEG diacrylate

About This Item

Recommended Products

product name

Poly(ethylene glycol) diacrylate, average Mn 6,000, contains ≤1500 ppm MEHQ as inhibitor

form

solid

mol wt

average Mn 6,000

contains

≤1500 ppm MEHQ as inhibitor

reaction suitability

reagent type: cross-linking reagent

reaction type: Polymerization Reactions

transition temp

Tm 59-63 °C

Ω-end

acrylate

α-end

acrylate

polymer architecture

shape: linear

functionality: homobifunctional

storage temp.

−20°C

SMILES string

OCCO.OC(=O)C=C

InChI

1S/C8H10O4/c1-3-7(9)11-5-6-12-8(10)4-2/h3-4H,1-2,5-6H2

InChI key

KUDUQBURMYMBIJ-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

Related Categories

General description

Application

It can be used as an alloying agent to prepare polymer membranes for gas separation applications. For example, an alloyed poly(Ether Block Amide)/ PEGDA membrane can be used for the separation of CO2/H2.

It can also be used as aprecursor to fabricate polymer electrolyte membranes(PEMs) for flexible Li-ionbatteries. The addition of PEGDA enhances the ionic conductivity, thermal stability,and mechanical toughness of PEMs.

Features and Benefits

- Highly hydrophilic

- Non-toxic

- Biocompatible

- Non-immunogenic

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Eye Dam. 1 - Skin Irrit. 2 - Skin Sens. 1

Storage Class Code

11 - Combustible Solids

WGK

WGK 1

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Personal Protective Equipment

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

In this article, we will discuss the benefits and limitations of several 2D and 3D scaffold patterning techniques that can be applied in the presence of cells. Although these methods will be discussed in the context of poly(ethylene glycol) (PEG)-based hydrogels, they can technically be applied to any optically transparent, photoactive substrate.

In the past two decades, tissue engineering and regenerative medicine have become important interdisciplinary fields that span biology, chemistry, engineering, and medicine.

Progress in biotechnology fields such as tissue engineering and drug delivery is accompanied by an increasing demand for diverse functional biomaterials. One class of biomaterials that has been the subject of intense research interest is hydrogels, because they closely mimic the natural environment of cells, both chemically and physically and therefore can be used as support to grow cells. This article specifically discusses poly(ethylene glycol) (PEG) hydrogels, which are good for biological applications because they do not generally elicit an immune response. PEGs offer a readily available, easy to modify polymer for widespread use in hydrogel fabrication, including 2D and 3D scaffold for tissue culture. The degradable linkages also enable a variety of applications for release of therapeutic agents.

Devising biomaterial scaffolds that are capable of recapitulating critical aspects of the complex extracellular nature of living tissues in a threedimensional (3D) fashion is a challenging requirement in the field of tissue engineering and regenerative medicine.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service