481939

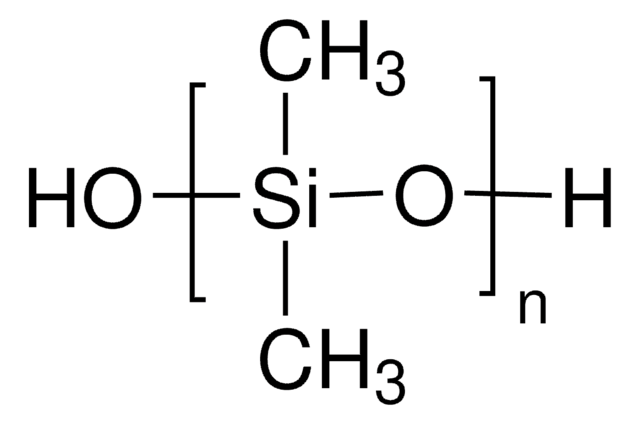

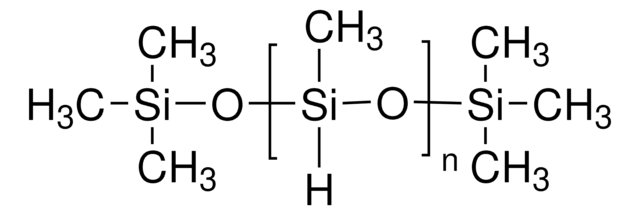

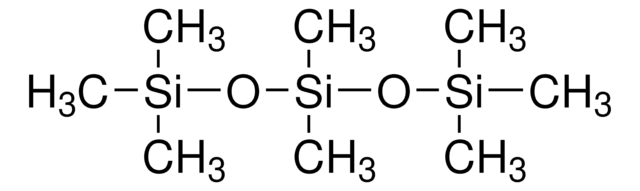

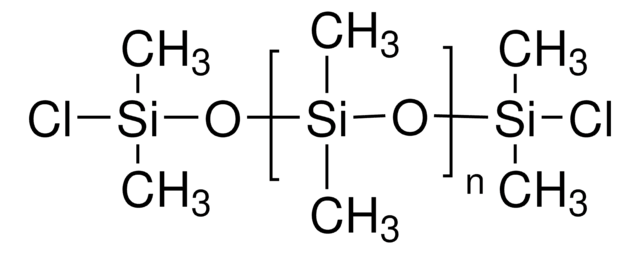

Poly(dimethylsiloxane), hydroxy terminated

viscosity ~25 cSt

Synonym(s):

PDMS

Sign Into View Organizational & Contract Pricing

All Photos(1)

About This Item

CAS Number:

MDL number:

UNSPSC Code:

12162002

PubChem Substance ID:

NACRES:

NA.23

Recommended Products

mol wt

average Mn ~550

Quality Level

refractive index

n20/D 1.405

viscosity

~25 cSt

bp

182 °C

density

0.95 g/mL at 25 °C

SMILES string

C[Si](C)(O)O

InChI

1S/C2H8O2Si/c1-5(2,3)4/h3-4H,1-2H3

InChI key

XCLIHDJZGPCUBT-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

Related Categories

General description

Polydimethylsiloxane(PDMS) is a silicon-basedorganic polymer that is nontoxic, optically clear, inert, and inflammablematerial. It is widely used in heat-resistant lubricants, fire retardants,medical devices, and cosmetics. Polydimethylsiloxane is hydrophobic,cytocompatible, and viscoelastic which can be used to prepare water-repellentcoatings in the textile industry.

Application

PDMS can be used as a precursor in the synthesis of poly(dimethylsiloxane-urethane) elastomers with improved mechanical and thermal properties.

PDMS is a material of choice for ophthalmic applications due to its high mechanical strength, transparency, and oxygen permeability. It can be used as a prepolymer to prepare a glucose permeable interpenetrating network of PDMS and poly (N-isopropyl acrylamide (PNIPAAM). These networks can be used in ophthalmic applications.

PDMS can also be used to synthesize fire and heat-resistant polyurethane-PDMS hybrids. The addition of PDMS provides low flammability and thermal stabilization to polyurethane under pyrolytic conditions.

PDMS is used as an additive to prepare TEOS-based stone protective hybrid crack-free xerogels. The addition of PDMS accelerates the gelling process and helps to achieve effective stone protection.

PDMS is a material of choice for ophthalmic applications due to its high mechanical strength, transparency, and oxygen permeability. It can be used as a prepolymer to prepare a glucose permeable interpenetrating network of PDMS and poly (N-isopropyl acrylamide (PNIPAAM). These networks can be used in ophthalmic applications.

PDMS can also be used to synthesize fire and heat-resistant polyurethane-PDMS hybrids. The addition of PDMS provides low flammability and thermal stabilization to polyurethane under pyrolytic conditions.

PDMS is used as an additive to prepare TEOS-based stone protective hybrid crack-free xerogels. The addition of PDMS accelerates the gelling process and helps to achieve effective stone protection.

Storage Class Code

10 - Combustible liquids

WGK

WGK 1

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Personal Protective Equipment

dust mask type N95 (US), Eyeshields, Gloves

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

L Liu et al.

Biomaterials, 26(3), 233-244 (2004-07-21)

Poly (dimethyl siloxane) (PDMS) has been widely used as a biomaterial in ophthalmic and other applications due to its good compatibility, high mechanical strength, excellent oxygen permeability and transparency. However, for use as an artificial cornea, contact lens and in

Articles

Advances in the area of soft optoelectronics, with a focus on the development of organic optoelectronic devices on shape memory polymers (SMP) is discussed.

Global Trade Item Number

| SKU | GTIN |

|---|---|

| 481939-100ML | 4061832389097 |

| 481939-500ML | 4061832389103 |

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service