931578

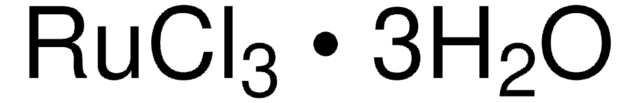

Ruthenium(III) chloride hydrate

≥99.9% trace metals basis

Synonym(s):

Ruthenium trichloride, Trichlororuthenium hydrate

About This Item

ethanol: soluble

water: soluble

Recommended Products

grade

for analytical purposes

Quality Level

Assay

≥99.9% trace metals basis

form

powder

impurities

≤1000.0 ppm (trace metals analysis)

solubility

acetone: soluble ((lit.))

ethanol: soluble

water: soluble

density

3.11 g/cm3

SMILES string

O.Cl[Ru](Cl)Cl

InChI

1S/3ClH.H2O.Ru/h3*1H;1H2;/q;;;;+3/p-3

InChI key

BIXNGBXQRRXPLM-UHFFFAOYSA-K

Looking for similar products? Visit Product Comparison Guide

General description

Industrially, ruthenium trichloride hydrate is produced by dissolving ruthenium oxides in hydrochloric acid. The hydrated salt is obtained by recrystallization.

Application

Another common application of ruthenium chloride hydrate is as a precursor for single-atom catalysts. For example, scientists have used ruthenium chloride hydrate for the synthesis of ruthenium single-atom-doped ZrO2 particles to catalyze nitrogen fixation and for the synthesis of ruthenium single-atom-doped MXenes to catalyze hydrogen evolution. A third common application of ruthenium chloride hydrate is in the synthesis of metal alloys, like PtRuIr, or PtRuFe, which are investigated for electrocatalysis, usually the oxidation of simple organics like methanol or formic acid.

For use in all these applications, also consider our higher-purity ruthenium chloride hydrate, 463779, with trace metals purity greater than 99.98%, which offers the best reproducibility and purity.

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Acute Tox. 4 Oral - Aquatic Chronic 2 - Eye Dam. 1 - Skin Corr. 1B

Storage Class Code

8A - Combustible corrosive hazardous materials

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Choose from one of the most recent versions:

Certificates of Analysis (COA)

It looks like we've run into a problem, but you can still download Certificates of Analysis from our Documents section.

If you need assistance, please contact Customer Support.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service