927201

TissueFab® bioink

(GelHA)ma -Vis/405nm, low endotoxin

Synonym(s):

HAMA bioink, HAMA-LAP, Hyaluronic Acid Methacrylate Bioink, Low endotoxin

Sign Into View Organizational & Contract Pricing

All Photos(1)

About This Item

UNSPSC Code:

12352201

NACRES:

NA.25

Recommended Products

Looking for similar products? Visit Product Comparison Guide

General description

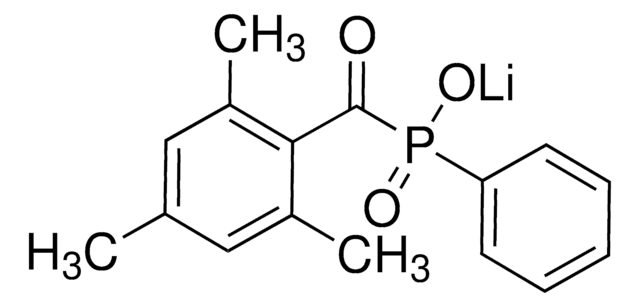

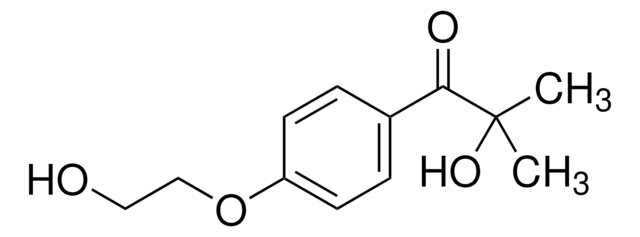

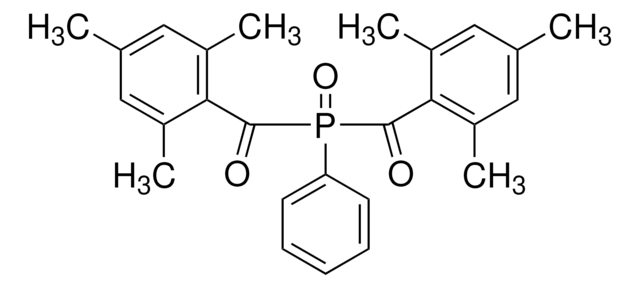

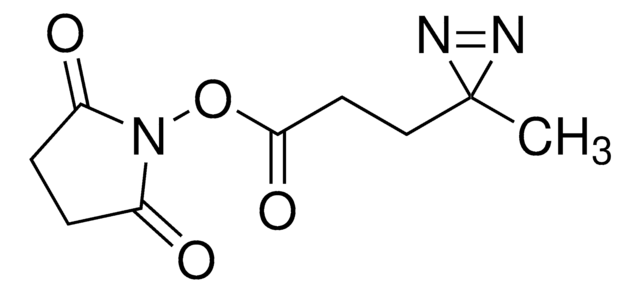

TissueFab bioink (GelHA)ma -Vis/405nm, low endotoxin bioink is a hyaluronic acid methacrylate and GelMA based bioink for 3D bioprinting applications. Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) is a water soluble, cytocompatible, Type I photoinitiator for use in the polymerization of hydrogels or other polymeric materials. This photoinitator is preferred over Irgacure 2959 for biological applications due to its increased water solubility, increased polymerization rates with 365 nm light, and absorbance at 400 nm allowing for polymerization with visible light.

Gelatin methacryloyl (GelMA) is a polymerizable hydrogel material derived from natural extracellular matrix (ECM) components. Due to its low cost, abundance, and retention of natural cell binding motifs, gelatin has become a highly sought material for tissue engineering applications. Hyaluronic acid (HA) is a linear polysaccharide of alternating D-glucuronic acid, and N-acetyl-D-glucosamine found in the extracellular matrix. HA is commonly chemically modified to form covalently crosslinked hydrogels.

Gelatin methacryloyl (GelMA) is a polymerizable hydrogel material derived from natural extracellular matrix (ECM) components. Due to its low cost, abundance, and retention of natural cell binding motifs, gelatin has become a highly sought material for tissue engineering applications. Hyaluronic acid (HA) is a linear polysaccharide of alternating D-glucuronic acid, and N-acetyl-D-glucosamine found in the extracellular matrix. HA is commonly chemically modified to form covalently crosslinked hydrogels.

Application

The formulation is optimized for 3D bioprinting of tissues and constructs using extrusion based 3D bioprinters, and can be can be used to bioprint cell-laden hydrogels in desired shape without any supporting material. The crosslinking of printed structures can be done in one step using visible light for further culture and maturation of cells for tissue engineering and regenerative medicine applications.

Low Endotoxin, low bioburden: Endotoxins have been demonstrated negatively impact cellular growth, morphology, differentiation, inflammation and protein expression. Bioburden is defined as the number of contaminated organisms found in a given amount of material. We test each lot for endotoxins as well as total bioburden (aerobic and fungal) to minimize unwanted interactions. For more information: https://www.sigmaaldrich.com/US/en/technical-documents/technical-article/microbiological-testing/pyrogen-testing/what-is-endotoxin

The protocol can be found under "More Documents" at the bottom of the page.

Low Endotoxin, low bioburden: Endotoxins have been demonstrated negatively impact cellular growth, morphology, differentiation, inflammation and protein expression. Bioburden is defined as the number of contaminated organisms found in a given amount of material. We test each lot for endotoxins as well as total bioburden (aerobic and fungal) to minimize unwanted interactions. For more information: https://www.sigmaaldrich.com/US/en/technical-documents/technical-article/microbiological-testing/pyrogen-testing/what-is-endotoxin

The protocol can be found under "More Documents" at the bottom of the page.

Legal Information

TISSUEFAB is a registered trademark of Merck KGaA, Darmstadt, Germany

Storage Class Code

10 - Combustible liquids

WGK

WGK 3

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Lot/Batch Number

Sorry, we don't have COAs for this product available online at this time.

If you need assistance, please contact Customer Support.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Michelle T Poldervaart et al.

PloS one, 12(6), e0177628-e0177628 (2017-06-07)

In bone regenerative medicine there is a need for suitable bone substitutes. Hydrogels have excellent biocompatible and biodegradable characteristics, but their visco-elastic properties limit their applicability, especially with respect to 3D bioprinting. In this study, we modified the naturally occurring

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service