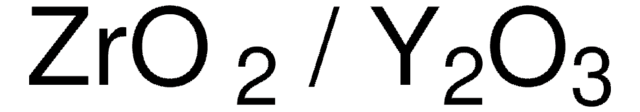

230693

Zirconium(IV) oxide

powder, 5 μm, 99% trace metals basis

Synonym(s):

Zirconia

About This Item

Recommended Products

Quality Level

Assay

99% trace metals basis

form

powder

reaction suitability

reagent type: catalyst

core: zirconium

particle size

5 μm

bp

5000 °C (lit.)

mp

2700 °C (lit.)

density

5.89 g/mL at 25 °C (lit.)

application(s)

battery manufacturing

SMILES string

O=[Zr]=O

InChI

1S/2O.Zr

InChI key

MCMNRKCIXSYSNV-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

General description

Application

Storage Class Code

13 - Non Combustible Solids

WGK

nwg

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Personal Protective Equipment

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Articles

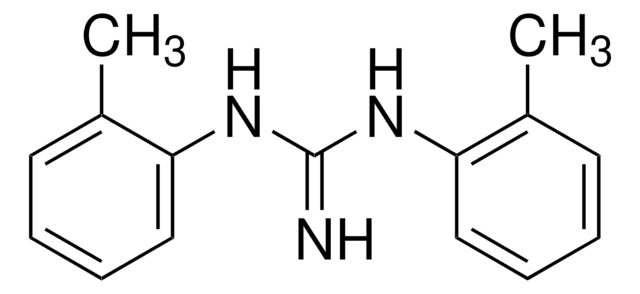

Innovation in dental restorative materials is driven by the need for biocompatible and natural-appearing restoration alternatives. Conventional dental materials like amalgam and composite resins have inherent disadvantages.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service