189480

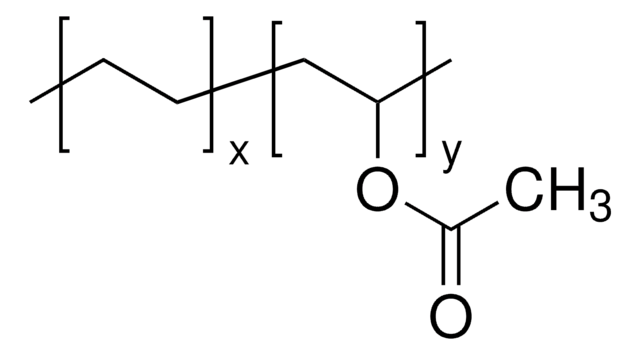

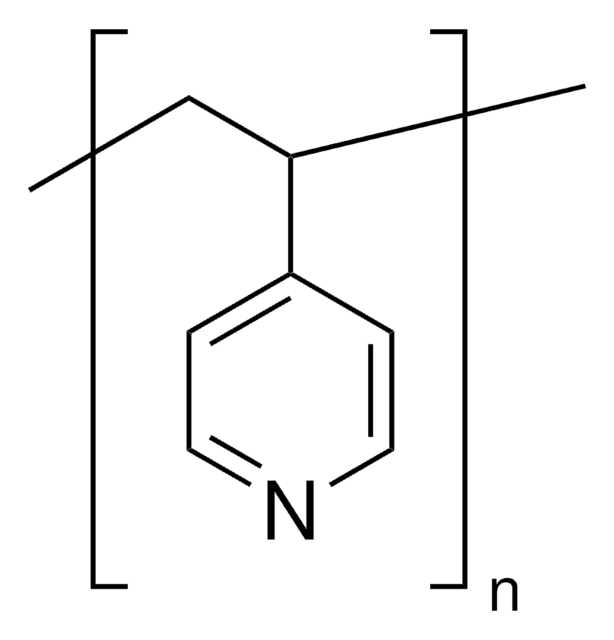

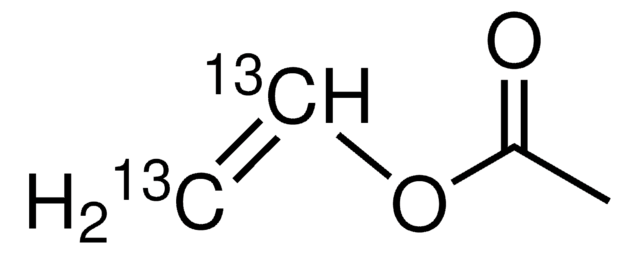

Poly(vinyl acetate)

average Mw ~100,000 by GPC, beads

Synonym(s):

Polyvinyl acetate

Sign Into View Organizational & Contract Pricing

All Photos(3)

About This Item

Linear Formula:

[CH2CH(O2CCH3)]n

CAS Number:

MDL number:

UNSPSC Code:

12162002

PubChem Substance ID:

NACRES:

NA.23

Recommended Products

form

beads

mol wt

average Mw ~100,000 by GPC

viscosity

17-21 sec.(25 °C, Ford, no. 4)(lit.)

density

1.18 g/mL at 25 °C

storage temp.

2-8°C

SMILES string

COC(=O)C=C

InChI

1S/C4H6O2/c1-3-6-4(2)5/h3H,1H2,2H3

InChI key

XTXRWKRVRITETP-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

General description

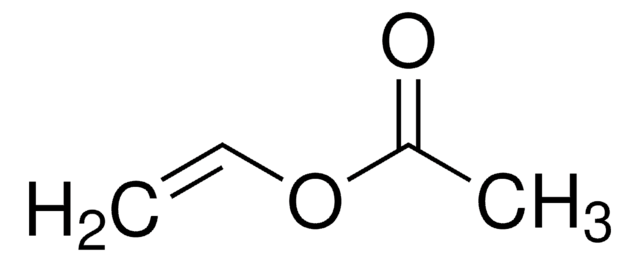

Poly(vinyl acetate) (PVAc) is a non-crystalline, atactic polymer. It is prepared from vinylacetate monomer via free radical polymerization. It is commonly usedin the food industry due to its low toxicity and excellent flexibility. PVAc films are used as emission sensors forvehicles and in oral drug delivery products.

Application

Poly(vinyl acetate) can be used as a:

- Starting material to prepare polymer fibers for gas and humidity sensor applications. Citric acid-doped PVAc nanofibrous mats can be used to develop sensors for trimethylamine gas at room temperature.

- Polymer coating for floating tablets showing a controlled drug delivery. PVAc is a suitable excipient to ensure reliable and safe drug release. PVAc-based matrix tablet flow due to intrinsic low density and high elasticity of polyvinyl acetate coating.

Storage Class Code

11 - Combustible Solids

WGK

nwg

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Personal Protective Equipment

dust mask type N95 (US), Eyeshields, Gloves

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

K Kolter et al.

International journal of pharmaceutics, 457(2), 470-479 (2013-10-01)

Polyvinyl acetate-based colloidal aqueous polymer dispersion Kollicoat(®) SR 30 D results in coatings characterized by moderate swelling behaviour, lipophilicity, pH-independent permeability for actives and high flexibility to withstand mechanical stress and is therefore used for controlled release coating. The colloidal

Cellulose nanofibrils/polyvinyl acetate nanocomposite adhesives with improved mechanical properties.

Ons Chaabouni et al.

Carbohydrate polymers, 156, 64-70 (2016-11-16)

Cellulose nanofibrils (CNFs) are nanoscale cellulose produced from renewable resources with strong reinforcing potential when included in a polymer matrix. In this work, the effect of the addition of CNFs on the properties of waterborne polyvinylacetate (PVA) adhesive was investigated.

Il Gyu Kang et al.

American journal of rhinology & allergy, 24(5), 392-395 (2011-01-20)

The aim of this study was to evaluate the effect of repeated expandable polyvinyl acetate (EPA) packing for preventing stenosis of the frontal sinus ostium after patients undergo functional endoscopic sinus surgery (FESS). A nonrandomized, prospective study of 20 patients

Dong-Hao Zhang et al.

Bioresource technology, 124, 233-236 (2012-09-20)

Poly(vinyl acetate-acrylamide) microspheres were synthesized in the absence or presence of isooctane via suspension polymerization and utilized as carriers to immobilize Candida rugosa lipase. When the hydrophobic/hydrophilic surface characteristics of the microspheres were modified by changing the ratio of vinyl

Ehab A Fouad et al.

Expert opinion on drug delivery, 8(5), 693-703 (2011-03-23)

Developments in industrial pharmacy are often linked to the discovery of pharmaceutical excipients. Although recently introduced as a material for immediate release coatings, Kollicoat IR already has other applications. In this review, the different properties and pharmaceutical applications of Kollicoat

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service