939722

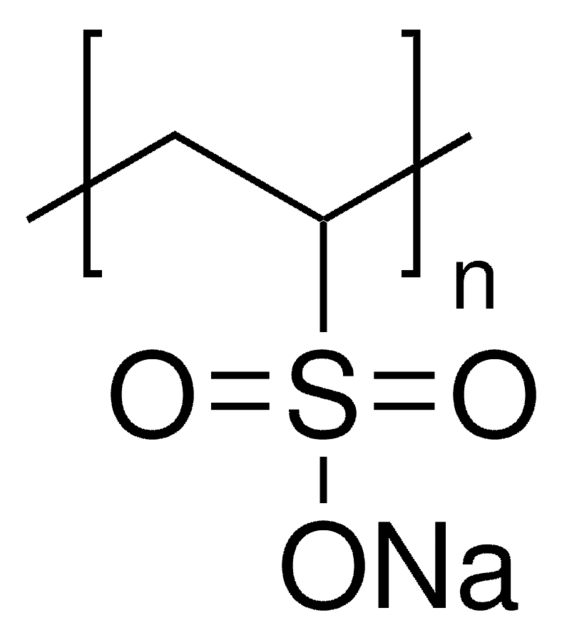

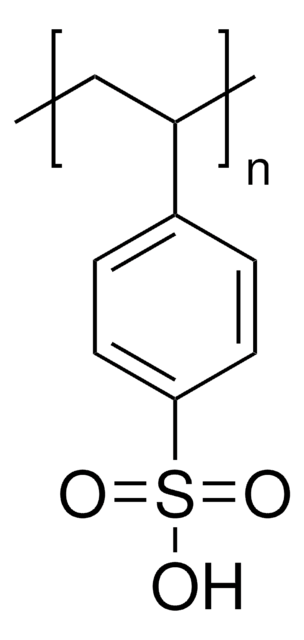

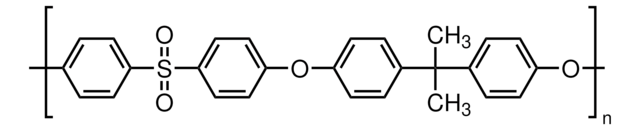

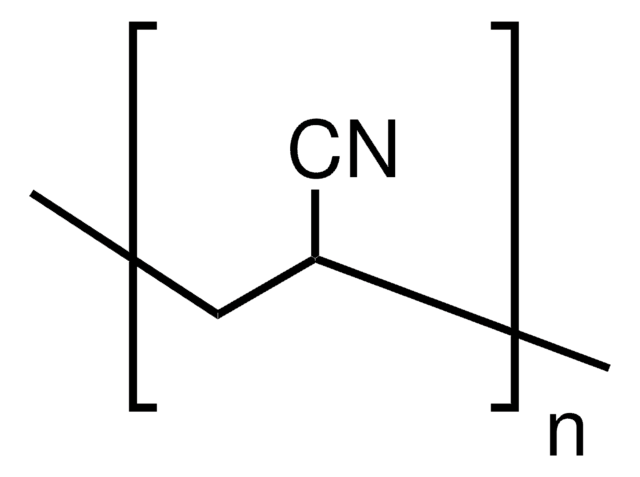

Sulfonated polysulfone

proton conducting polymer, degree of sulfonation 70%

Synonym(s):

Sulfonated aromatic polymer for fuel cells and PEMs, Sulfonated poly(arylene ether sulfone) ionomer

About This Item

Recommended Products

description

degree of sulfonation: 60-90%

Quality Level

form

powder

mol wt

20-80 kDa

color

white to beige

mp

>300 °C

functional group

sulfonic acid

polymer architecture

shape: linear

InChI

1S/C12H8F2O8S3.C12H8F2O2S.C12H10O2.2Na/c13-9-3-1-7(5-11(9)24(17,18)19)23(15,16)8-2-4-10(14)12(6-8)25(20,21)22;13-9-1-5-11(6-2-9)17(15,16)12-7-3-10(14)4-8-12;13-11-5-1-9(2-6-11)10-3-7-12(14)8-4-10;;/h1-6H,(H,17,18,19)(H,20,21,22);1-8H;1-8,13-14H;;

InChI key

MSKVMJLWNYCWLA-UHFFFAOYSA-N

General description

Application

Moreover, sulfonated aromatic polymers are employed in water treatment membranes for processes like reverse osmosis, nanofiltration, and ultrafiltration. Their chemical resistance allows them to withstand harsh environments while maintaining high water permeability, effectively separating and purifying water. These polymers are also explored for their potential in gas separation membranes, where they can selectively separate gases for various industrial processes. Continued research and development in this area promise further advancements and innovations in fuel cells, energy storage, water treatment, and gas separation.

related product

Storage Class Code

11 - Combustible Solids

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Sorry, we don't have COAs for this product available online at this time.

If you need assistance, please contact Customer Support.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service