914169

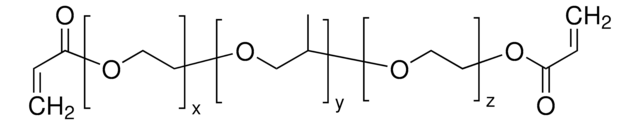

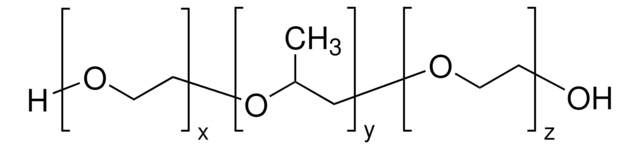

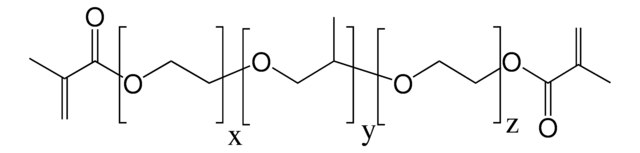

Poly(ethylene glycol)-block-poly(propylene glycol)-block-poly(ethylene glycol) dimethacrylate

average Mn ~12,500

Synonym(s):

PEG-PPG-PEG, Pluronic Dimethacrylate, Pluronic F-127 dimethacrylate

Sign Into View Organizational & Contract Pricing

All Photos(1)

About This Item

Linear Formula:

C4H5O[C2H4O]x[C3H6O]y[C2H4O]zC4H5O2

UNSPSC Code:

12162002

NACRES:

NA.23

Recommended Products

Looking for similar products? Visit Product Comparison Guide

Application

Poloxamers are nonionic, triblock copolymers containg a central hydrophobic chain of poly(propylene glycol) (PPG) and two terminal hydrophilic chains of poly(ethylene glycol) (PEG). Due to their amphiphilic structure, poloxamer solutions feature temperature dependent self-assembling and thermo-gelling behavior. Concentrated aqueous solutions of poloxamers are liquid at low temperature and form a gel at higher temperature, in a reversible process. This characteristic has allowed for these materials to be used as drug carriers for most routes of administration including oral, topical, intranasal, ocular, and parenteral. Methacrylate-modified derivatives are most commonly used as thermosensitive hydrogels for drug delivery and 3D bioprinting applications. After casting or printing, the material can be crosslinked to preserve the hydrogel structure.

Storage Class Code

11 - Combustible Solids

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Lot/Batch Number

Sorry, we don't have COAs for this product available online at this time.

If you need assistance, please contact Customer Support.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Photopolymerization of Pluronic F127 diacrylate: a colloid-templated polymerization.

Biase M D, et al.

Soft Materials, 7, 4928-4937 (2011)

Christopher J Hansen et al.

Advanced materials (Deerfield Beach, Fla.), 25(1), 96-102 (2012-10-31)

Microvascular multinozzle arrays are designed and fabricated for high-throughput printing of functional materials. Ink-flow uniformity within these multigeneration, bifurcating microchannel arrays is characterized by computer modeling and microscopic particle image velocimetry (micro-PIV) measurements. Both single and dual multinozzle printheads are

Michael Müller et al.

Biofabrication, 7(3), 035006-035006 (2015-08-12)

Bioprinting is an emerging technology in the field of tissue engineering as it allows the precise positioning of biologically relevant materials in 3D, which more resembles the native tissue in our body than current homogenous, bulk approaches. There is however

Leo Benning et al.

Journal of biomedical materials research. Part A, 105(12), 3231-3241 (2017-08-07)

Mesenchymal stem cells (MSCs) represent a very attractive cell source for tissue engineering applications aiming at the generation of artificial bone substitutes. The use of three-dimensional bioprinting technologies has the potential to improve the classical tissue engineering approach because bioprinting

Photopolymerization of Pluronic F127 diacrylate: a colloid-templated polymerization.

Manuela D B, et al.

Soft Materials, 7, 4928-4937 (2011)

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service