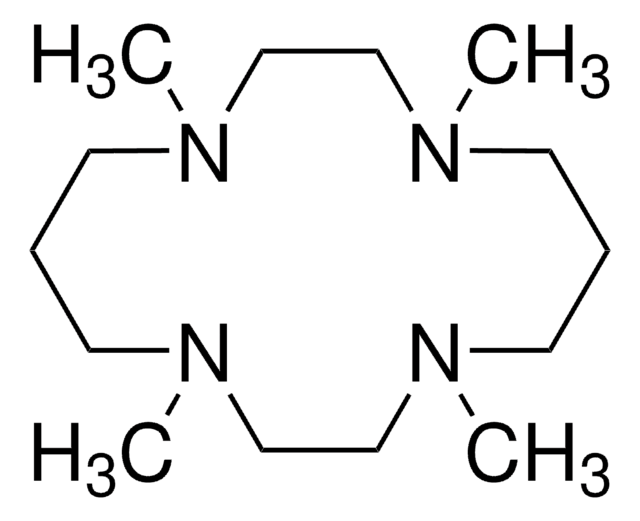

369497

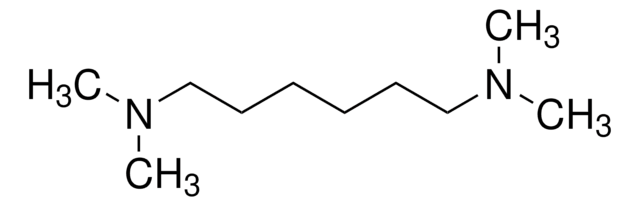

N,N,N′,N′′,N′′-Pentamethyldiethylenetriamine

99%

Synonym(s):

PMDETA, PMDTA

About This Item

Recommended Products

vapor pressure

0.23 mmHg ( 20 °C)

Quality Level

Assay

99%

form

liquid

autoignition temp.

311 °F

expl. lim.

5.6 %

refractive index

n20/D 1.442 (lit.)

bp

198 °C (lit.)

mp

−20 °C (lit.)

density

0.83 g/mL at 25 °C (lit.)

SMILES string

CN(C)CCN(C)CCN(C)C

InChI

1S/C9H23N3/c1-10(2)6-8-12(5)9-7-11(3)4/h6-9H2,1-5H3

InChI key

UKODFQOELJFMII-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

General description

Application

- A catalyst in the synthesis of multifunctional silicone acrylate prepolymers for use in UV-curable coatings.

- A multifunctional initiating and cross-linking agent in the synthesis of polyacrylamide hydrogels. It improves the mechanical properties of the hydrogels, such as toughness and resilience, without compromising their biocompatibility.

- An organocatalyst in ring-opening polymerization (ROP) of trimethylene carbonate. This catalyst can be easily removed after the reaction compared to metal catalysts.

- A catalyst along with CuBr to synthesize a series of side-chain azobenzene poly(meth)acrylates via the atom transfer radical polymerization(ATRP) technique.

- An initiator to grow polystyrene chains to prepare polyolefin-polystyrene copolymers.

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Acute Tox. 3 Dermal - Acute Tox. 4 Oral - Eye Dam. 1 - Skin Corr. 1B

Storage Class Code

6.1A - Combustible acute toxic Cat. 1 and 2 / very toxic hazardous materials

WGK

WGK 2

Flash Point(F)

168.8 °F - closed cup

Flash Point(C)

76 °C - closed cup

Personal Protective Equipment

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Tools and techniques for performing atom transfer radical polymerization (ATRP) with benefits and limitations.

Atom transfer radical polymerization (ATRP) has emerged as one of the most successful synthetic techniques for the preparation of polymers with predetermined molecular weights, narrow molecular weight distributions, and high degrees of chain end functionalities.

Find how atom transfer radical polymerization (ATRP) tools can be used for the synthesis of well-defined functionalized polymers.

ATRP polymerization, chain transfer agent, living polymerization, functional telechelic polymers

Protocols

Sigma-Aldrich presents an article about RAFT, or Reversible Addition/Fragmentation Chain Transfer, which is a form of living radical polymerization.

We presents an article featuring procedures that describe polymerization of methyl methacrylate and vinyl acetate homopolymers and a block copolymer as performed by researchers at CSIRO.

Sigma-Aldrich presents an article about the typical procedures for polymerizing via ATRP, which demonstrates that in the following two procedures describe two ATRP polymerization reactions as performed by Prof. Dave Hadddleton′s research group at the University of Warwick.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

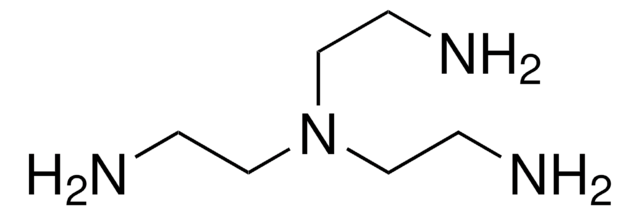

Contact Technical Service![Tris[2-(dimethylamino)ethyl]amine 97%](/deepweb/assets/sigmaaldrich/product/structures/695/792/ee0ff167-22a3-43a7-83a1-6c4908adf0ae/640/ee0ff167-22a3-43a7-83a1-6c4908adf0ae.png)

![Bis[2-(N,N-dimethylamino)ethyl] ether 97%](/deepweb/assets/sigmaaldrich/product/structures/372/323/505a46ae-b067-4177-8e5f-19a3f4ef9c44/640/505a46ae-b067-4177-8e5f-19a3f4ef9c44.png)