8.00609

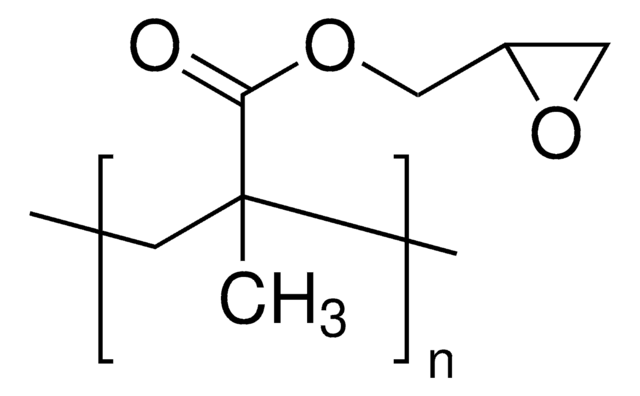

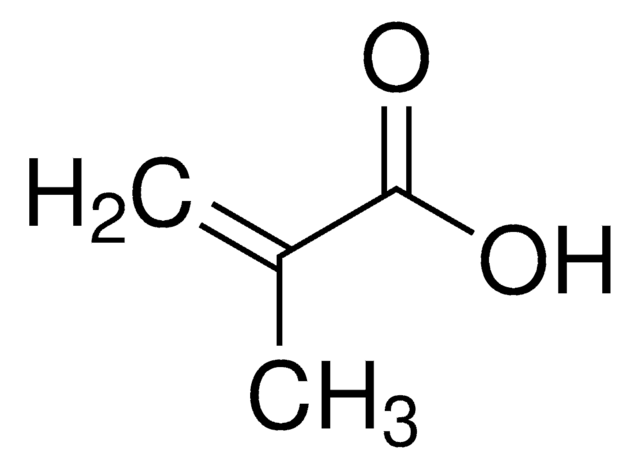

2,3-Epoxypropyl methacrylate

Technipur®, for synthesis

Sinónimos:

Glycidyl methacrylate, 2-((Methacryloxy)methyl)oxirane, 2,3-Epoxypropyl methacrylate, Methacrylic acid 2,3-epoxypropyl ester

About This Item

Productos recomendados

grade

for synthesis

Quality Level

vapor pressure

4.2 hPa ( 25 °C)

refractive index

n20/D 1.449 (lit.)

bp

189 °C (lit.)

mp

<-60 °C

density

1.042 g/mL at 25 °C (lit.)

1.07 g/cm3 at 25 °C

SMILES string

CC(=C)C(=O)OCC1CO1

InChI

1S/C7H10O3/c1-5(2)7(8)10-4-6-3-9-6/h6H,1,3-4H2,2H3

InChI key

VOZRXNHHFUQHIL-UHFFFAOYSA-N

¿Está buscando productos similares? Visita Guía de comparación de productos

General description

Application

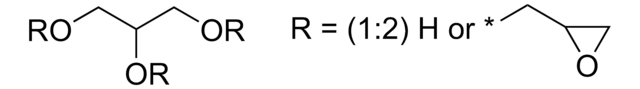

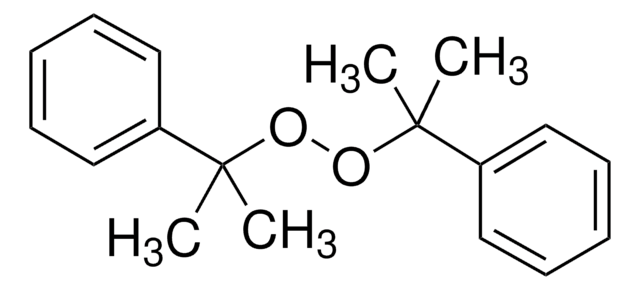

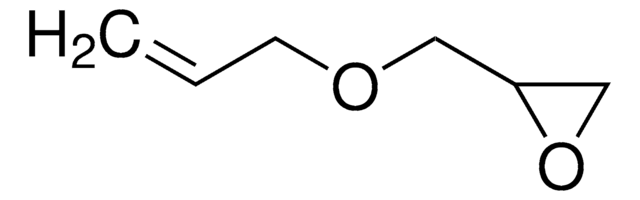

It is also used to prepare poly(n-butyl methacrylate-co-glycidyl methacrylate) copolymers, which find applications in adhesives, surface coatings, and electrical devices in various polymeric industries. The presence of epoxy groups and flexible butyl groups in epoxy resin-modified copolymers increases its mechanical properties, impact strength, and fracture elongation.

Legal Information

signalword

Danger

Hazard Classifications

Acute Tox. 3 Dermal - Acute Tox. 4 Oral - Carc. 1B - Eye Dam. 1 - Muta. 2 - Repr. 1B - Skin Corr. 1C - Skin Sens. 1 - STOT RE 1 - STOT SE 3

target_organs

Respiratory system

Storage Class

6.1C - Combustible, acute toxic Cat.3 / toxic compounds or compounds which causing chronic effects

wgk_germany

WGK 3

flash_point_f

168.8 °F - closed cup

flash_point_c

76 °C - closed cup

Certificados de análisis (COA)

Busque Certificados de análisis (COA) introduciendo el número de lote del producto. Los números de lote se encuentran en la etiqueta del producto después de las palabras «Lot» o «Batch»

¿Ya tiene este producto?

Encuentre la documentación para los productos que ha comprado recientemente en la Biblioteca de documentos.

Nuestro equipo de científicos tiene experiencia en todas las áreas de investigación: Ciencias de la vida, Ciencia de los materiales, Síntesis química, Cromatografía, Analítica y muchas otras.

Póngase en contacto con el Servicio técnico