TRD3D0027

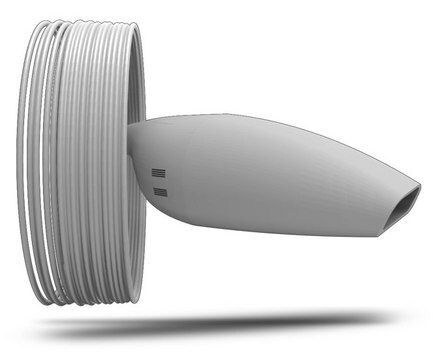

Performance ABS 3D Printing Filament

black hole, diam. 1.75 mm

About This Item

Productos recomendados

greener alternative product characteristics

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

diam.

1.75 mm

weight

1 kgeach

greener alternative category

, Enabling

¿Está buscando productos similares? Visita Guía de comparación de productos

General description

- Acrylonitrile Butadiene Styrene (ABS) is a polymer known for its toughness, brilliance and tactile feeling

- It is used in many areas, such as appliance shells and gears, cosmetics containers and industrials with power plugs, driving bar coverings and much more

- Our special formulation reduces offensive odors, making our ABS filaments very efficient

Material Properties

- Density: 1.04 g/cm3

- Tensile modulus: 2300 Mpa

- Tensile strengh at yield: 2.6%

- Flexural strength: 65%

- IZOD impact strength notched 23 °C: 29 kJ/m2

- Water absorption: 1%

- MFR: 19g/10 min

- Vicat softening temperature: 90 °C

Application

- Extruder (nozzle) temperature: 230 +/-10 °C

- Bed temperature: 100 +/-10 °C

- Print speed: 60-90 mm/s

- Fan: 0-30 %

- Minimum nozzle diameter: 0.3 mm

- Plate materials: kapton tape, abs glue, etc.

Application Notes:

- To enhance the brightness and smooth the finish, objects printed can be processed with acetone gas (Always be careful to take proper safety measures)

- Warping of the final object can be reduced using a heated bed

- Sun exposure weakens the ABS, not recommended for use in outdoor applications

Storage Class

11 - Combustible Solids

wgk_germany

WGK 3

flash_point_f

Not applicable

flash_point_c

Not applicable

Elija entre una de las versiones más recientes:

Certificados de análisis (COA)

Lo sentimos, en este momento no disponemos de COAs para este producto en línea.

Si necesita más asistencia, póngase en contacto con Atención al cliente

¿Ya tiene este producto?

Encuentre la documentación para los productos que ha comprado recientemente en la Biblioteca de documentos.

Nuestro equipo de científicos tiene experiencia en todas las áreas de investigación: Ciencias de la vida, Ciencia de los materiales, Síntesis química, Cromatografía, Analítica y muchas otras.

Póngase en contacto con el Servicio técnico