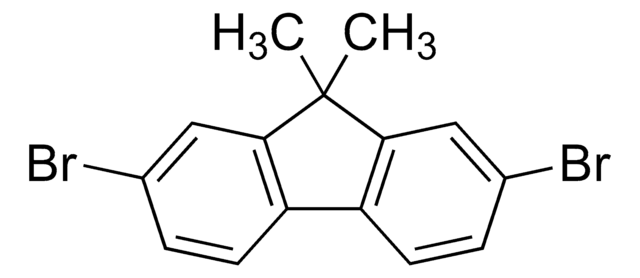

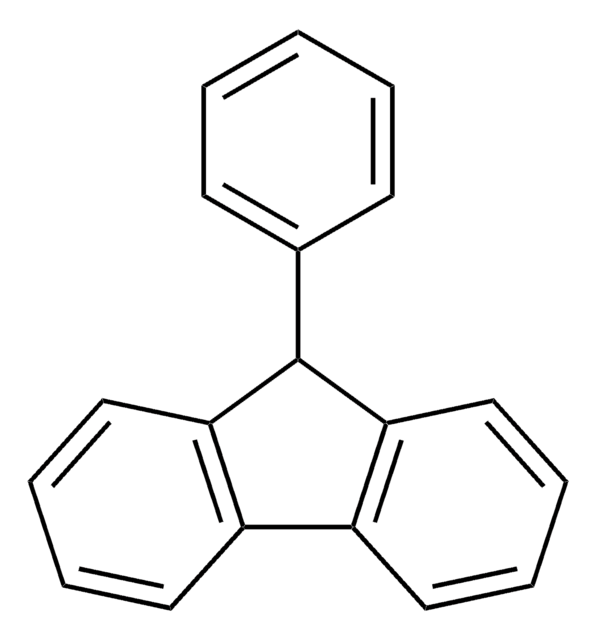

918059

1 M 9,9-dimethylfluorene in THF

a precursor solution to prepare the prelithiation reagent for Si anode

About This Item

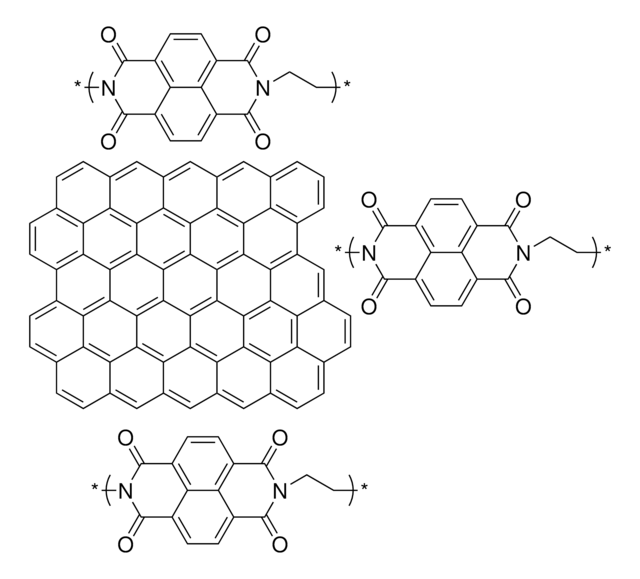

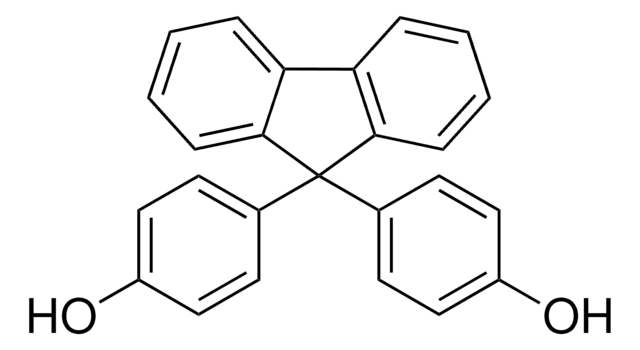

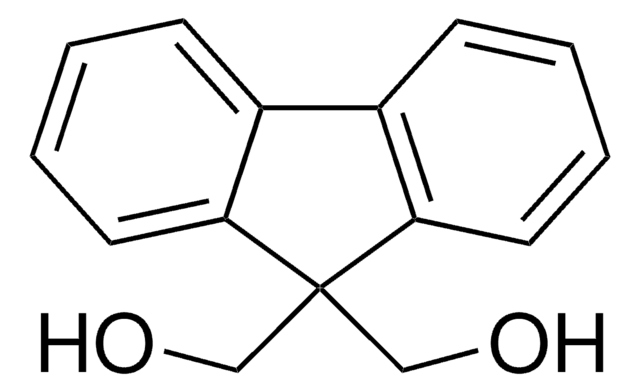

Recommended Products

Quality Level

form

liquid

impurities

≤1000 ppm H2O

application(s)

battery manufacturing

storage temp.

2-8°C

SMILES string

CC1(C)C2=C(C=CC=C2)C3=C1C=CC=C3

InChI

1S/C15H14/c1-15(2)13-9-5-3-7-11(13)12-8-4-6-10-14(12)15/h3-10H,1-2H3

InChI key

ZHQNDEHZACHHTA-UHFFFAOYSA-N

Application

Recommended instructions (this should be a separate document):Soak your electrode with the anode material coated on a copper current collector in this prelithiation reagent for a set amount of time. Discard the solution and then wash your electrode twice with THF. For a 1cm diameter electrode with 1∼3 mg acitve material per cm2, use 0.5∼1 mL of prelithiation solution will be enough. You can use an empty coin cell casing as the treatment vessel. Electrode soaking time is important and may need to be optimized for your application. A good time to try is ∼10 min. Longer prelithiation time may cause eletrode structure deformation, leading to a decreased discharge/charge capacity.

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Acute Tox. 4 Oral - Aquatic Chronic 2 - Carc. 2 - Eye Irrit. 2 - Flam. Liq. 2 - STOT SE 3

Target Organs

Central nervous system, Respiratory system

Supplementary Hazards

Storage Class Code

3 - Flammable liquids

WGK

WGK 3

Flash Point(F)

1.4 °F

Flash Point(C)

-17.0 °C

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Don't see the Right Version?

If you require a particular version, you can look up a specific certificate by the Lot or Batch number.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service