773840

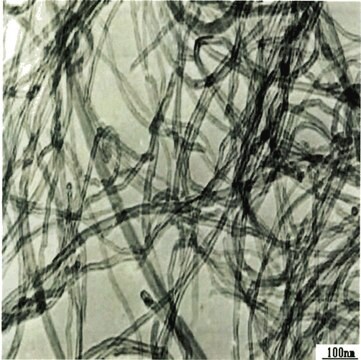

Carbon nanotube, multi-walled

≥98% carbon basis, O.D. × I.D. × L 10 nm ± 1 nm × 4.5 nm ± 0.5 nm × 3-~6 μm, TEM, avg. no. of layers, 6 ‑ 8

Synonym(s):

SMW200, MWCNT, MWNT, Multiwall carbon nanotube

Sign Into View Organizational & Contract Pricing

All Photos(3)

About This Item

CAS Number:

UNSPSC Code:

12352103

Recommended Products

Assay

≥98% carbon basis

form

powder

feature

avg. no. of layers 6 ‑ 8

O.D. × I.D. × L

10 nm ± 1 nm × 4.5 nm ± 0.5 nm × 3-~6 μm, TEM

surface area

280-350 m2/g , BET

mp

3652-3697 °C (lit.)

density

~2.1 g/mL at 25 °C (lit.)

bulk density

0.068 g/cm3

Looking for similar products? Visit Product Comparison Guide

General description

Number of Walls: 6-8 tube walls (typically). Multi walled carbon nanotubes (MWNTs, CNTs) were prepared by chemical vapor deposition (CVD) using cobalt and molybdenum as catalysts (CoMoCAT).In chemical vapor deposition (CVD), a volatile precursor undergoes thermal decomposition at elevated temperatures to form a solid deposit on a substrate. Compared to other techniques CVD produces greater yield of carbon nanotubes. Morphology and structure of the nanotubes can be easily tuned using CVD technique. The CNTs formed can be formed in bundles over a catalyst support or in patterns over substrates.1

Application

Carbon nanotube, multi-walled (MWNT) belongs to the class of carbonaceous materials with excellent physiochemical, thermo-mechanical and electrochemical properties. This material can be used in a variety of sustainable energy applications such as solar cells, photocatalysis, biosensor, gas sensor, supercapacitor and as a filler that acts as a reinforcement to improve the mechanical property of composites.

New generation of specialty multi-walled carbon nanotubes enable polymer composites with higher conductivity;easier to disperse and mechanical properties for advanced applications like conductive polymers or Li-ion battery cathodes.

Physical properties

Aspect ratio: > 350-550 (determined by AFM)

Preparation Note

CoMoCAT™ Catalytic Chemical Vapor Deposition (CVD) Method

Legal Information

Product of SouthWest NanoTechnologies;Inc. CoMoCAT® is a Registered Trademark of SouthWest NanoTechnologies;Inc.

SWeNT is a registered trademark of Southwest NanoTechnologies;Inc.

SWeNT is a registered trademark of Southwest NanoTechnologies;Inc.

CoMoCAT is a trademark of Chasm Advanced Materials

Storage Class Code

11 - Combustible Solids

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

B. Jin et al.

Electrochemical Communications, 10, 10537-11540 (2008)

K. Sheem et al.

Journal of Power Sources, 158, 1425-1430 (2006)

Olli Pitkänen et al.

Nanotechnology, 31(49), 495403-495403 (2020-09-26)

There is ever increasing demand for flexible energy storage devices due to the development of wearable electronics and other small electronic devices. The electrode flexibility is best provided by a special set of nanomaterials, but the required methodology typically consists

S.K. Martha et al.

Journal of Power Sources, 189, 288-296 (2009)

Claudia Angélica Ramírez-Herrera et al.

Nanomaterials (Basel, Switzerland), 9(2) (2019-02-13)

The demand for multifunctional requirements in aerospace, military, automobile, sports, and energy applications has encouraged the investigation of new composite materials. This study focuses on the development of multiwall carbon nanotube (MWCNT) filled polypropylene composites and carbon nanofiber composite mats.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service