765198

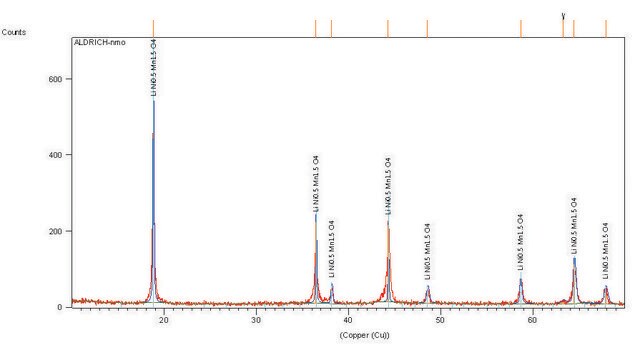

Lithium manganese nickel oxide

electrode sheet, aluminum substrate, size 5 in. × 10 in.

Synonym(s):

LMNO, Lithium nickel manganate

About This Item

Recommended Products

grade

battery grade

description

Nominal Voltage: 4.7 V, Li/Li+

Assay

≥98%

form

solid

composition

loading, ≥80%

greener alternative product characteristics

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

extent of labeling

≥80% loading

size

5 in. × 10 in.

thickness

25-50 μm

particle size

4-7 μm (typical)

capacity

115 mAh/g(minimum)

125 mAh/g(nominal at 0.1C)

mp

>1000 °C

application(s)

battery manufacturing

greener alternative category

, Enabling

SMILES string

[Li+].[Li+].[O-][Mn]=O.[O-][Ni]=O.O=[Mn]=O.O=[Mn]=O

InChI

1S/2Li.3Mn.Ni.8O/q2*+1;;;;;;;;;;;2*-1

InChI key

NTWFBJKNXFUJHM-UHFFFAOYSA-N

General description

Application

The LMNO casted electrode sheets can be cut into appropriate size and is ready to be used in lithium ion batteries.

Other Notes

Operating Condiditons:

- Recommended maximum charge voltage: 5.0 V vs Li/Li+

- Recommended maximum charge current: 5 C

- Recommended cut-off voltage for discharge: 3.5 V vs Li/Li+

- Recommended maximum discharge current: 5 C

- Recommended charge method: constant current - constant voltage

Signal Word

Warning

Hazard Statements

Precautionary Statements

Hazard Classifications

Carc. 2 - Skin Sens. 1

Storage Class Code

11 - Combustible Solids

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Don't see the Right Version?

If you require a particular version, you can look up a specific certificate by the Lot or Batch number.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Professor Qiao’s laboratory lays out recent advances in conversion type lithium metal fluoride batteries. This review explores key concepts in developing electrochemically stable microstructures for wide Li-ion insertion channels.

Electrode Materials for Lithium Ion Batteries

Lithium-ion batteries (LIBs) have been widely adopted as the most promising portable energy source in electronic devices because of their high working voltage, high energy density, and good cyclic performance.

The critical technical challenges associated with the commercialization of electric vehicle batteries include cost, performance, abuse tolerance, and lifespan.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service