추천 제품

material

angled neck

polystyrene

polystyrene flask

screw top cap

무균

sterile

특징

with cap vented

포장

pack of 10

case of 360

제조업체/상표

TPP 90025

용량

15 mL

외부 길이 × 너비 × 높이

90 mm × 50 mm × 25 mm

표면적

25 cm2 , growth surface (cm2)

작업 용적

3-5 mL

적합성

suitable for (cell culture; tissue culture)

결합 유형

Tissue Culture (TC)-treated surface

유사한 제품을 찾으십니까? 방문 제품 비교 안내

일반 설명

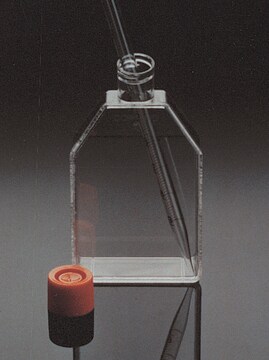

TPP Tissue Culture Flasks

Inside surface treatment by TPP provides an optimal growth surface on the flask base for the most varied matrix-dependent tissue cultures. The untreated side and top inside surfaces reduce the amount of cell loss during the separation phases, because undesired tissue adhesion outside the growth zone is diminished.

The flask′s innovative shape is of such a design that devices inserted through the flask′s neck have optimal access to the entire base surface. This means that there are no "dead" corners that cannot be reached with pipettes or cell scrapers. This excellent accessibility is due to the large neck opening and the favorable angle of inclination. The angled neck also reduces the chance of accidental spills and permits "dribble-free" pouring.

The TPP filter cap has a welded membrane in the cap cavity to offer free gas exchange without gas flow alteration. For optimal flask breathing, all membranes are proportionally dimensioned to each cap size. The microporous hydrophobic membrane (cytotoxic free) itself is constructed of 2 layers of membrane material based on a white acrylic copolymer over nylon support. With an airflow rate of 4.5 (LPM /3.7 cm2/ 13.5 psi), the gas exchange properties of the filtered flasks are comparable to that of the standard cap flasks.

The TPP tissue culture flasks stand for high quality aspects.

Advantages of the tissue culture flask:

For optimum tissue growth, the growth area is opto-mechanical treated. This enhances cell adhesion and cell growth.

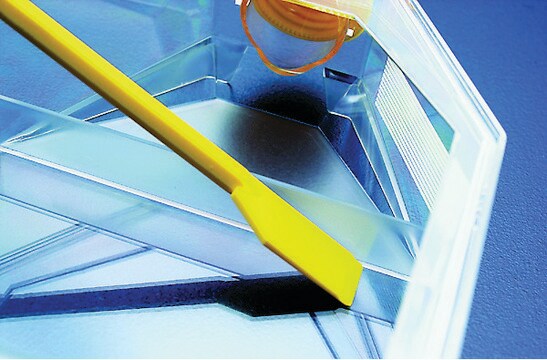

The geometry of the neck guarantees total access of TPP pipettes, TPP scrappers and the TPP spatula.

Inside surface treatment by TPP provides an optimal growth surface on the flask base for the most varied matrix-dependent tissue cultures. The untreated side and top inside surfaces reduce the amount of cell loss during the separation phases, because undesired tissue adhesion outside the growth zone is diminished.

The flask′s innovative shape is of such a design that devices inserted through the flask′s neck have optimal access to the entire base surface. This means that there are no "dead" corners that cannot be reached with pipettes or cell scrapers. This excellent accessibility is due to the large neck opening and the favorable angle of inclination. The angled neck also reduces the chance of accidental spills and permits "dribble-free" pouring.

The TPP filter cap has a welded membrane in the cap cavity to offer free gas exchange without gas flow alteration. For optimal flask breathing, all membranes are proportionally dimensioned to each cap size. The microporous hydrophobic membrane (cytotoxic free) itself is constructed of 2 layers of membrane material based on a white acrylic copolymer over nylon support. With an airflow rate of 4.5 (LPM /3.7 cm2/ 13.5 psi), the gas exchange properties of the filtered flasks are comparable to that of the standard cap flasks.

The TPP tissue culture flasks stand for high quality aspects.

Advantages of the tissue culture flask:

- Uniform even surface of the growth area

- Crystal clear transparency

- Stable, slip-free stacking of several flasks

- Bilateral marking area

- Accurate volume scale for optic control of the filling volume

- Excellent access of pipettes, tissue scrapers and tissue spatula

- Marking area with lines on both sides to allow your identification

- Increased overflow height reduces the danger of slopover of media

- "VENT" and filter screw caps

For optimum tissue growth, the growth area is opto-mechanical treated. This enhances cell adhesion and cell growth.

The geometry of the neck guarantees total access of TPP pipettes, TPP scrappers and the TPP spatula.

The inside surface treatment by TPP provides an optimal growth surface on the flask base for the most varied matrix-dependent tissue cultures. The untreated side and top inside surfaces reduce the amount of cell loss during the separation phases, because undesired tissue adhesion outside the growth zone is diminished. The flask′s innovative shape is of such a design that devices inserted through the flask′s neck have optimal access to the entire base surface. This means that there are no "dead" corners that cannot be reached with pipettes or cell scrapers.

This excellent accessibility is due to the large neck opening and the favorable angle of inclination. The angled neck also reduces the chance of accidental spills and permits "dribble-free" pouring.

When the vented screw cap is tightened to the end position, the closed tissue culture flask is liquid and gas tight. By simply unscrewing the cap one quarter of a turn, the flask is in the "VENT" position, with the inside of the flask being aerated through a defined gap opening. This guarantees that the gas exchange with the environment and the possible risk of contamination are kept to a minimum. In addition, the special flat thread profile of the caps stops excess tightening and thus allows the caps to be re-used multiple times.

The TPP filter cap has a welded membrane in the cap cavity to offer free gas exchange without gas flow alteration. For optimal flask breathing, all membranes are proportionally dimensioned to each cap size. The microporous hydrophobic membrane (cytotoxic free) itself is constructed of 2 layers of membrane material based on a white acrylic copolymer over nylon support. With an airflow rate of 4.5 (LPM/3.7cm2/13.5psi), the gas exchange properties of the filtered flasks are comparable to that of the standard cap flasks.

This excellent accessibility is due to the large neck opening and the favorable angle of inclination. The angled neck also reduces the chance of accidental spills and permits "dribble-free" pouring.

When the vented screw cap is tightened to the end position, the closed tissue culture flask is liquid and gas tight. By simply unscrewing the cap one quarter of a turn, the flask is in the "VENT" position, with the inside of the flask being aerated through a defined gap opening. This guarantees that the gas exchange with the environment and the possible risk of contamination are kept to a minimum. In addition, the special flat thread profile of the caps stops excess tightening and thus allows the caps to be re-used multiple times.

The TPP filter cap has a welded membrane in the cap cavity to offer free gas exchange without gas flow alteration. For optimal flask breathing, all membranes are proportionally dimensioned to each cap size. The microporous hydrophobic membrane (cytotoxic free) itself is constructed of 2 layers of membrane material based on a white acrylic copolymer over nylon support. With an airflow rate of 4.5 (LPM/3.7cm2/13.5psi), the gas exchange properties of the filtered flasks are comparable to that of the standard cap flasks.

법적 정보

TPP is a registered trademark of TPP Techno Plastic Products AG

가장 최신 버전 중 하나를 선택하세요:

이미 열람한 고객

자사의 과학자팀은 생명 과학, 재료 과학, 화학 합성, 크로마토그래피, 분석 및 기타 많은 영역을 포함한 모든 과학 분야에 경험이 있습니다..

고객지원팀으로 연락바랍니다.