D49504

Dibutyl sebacate

technical grade

동의어(들):

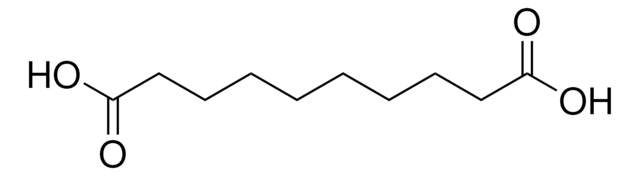

Decanedioic acid dibutyl ester, Sebacic acid dibutyl ester

로그인조직 및 계약 가격 보기

모든 사진(1)

About This Item

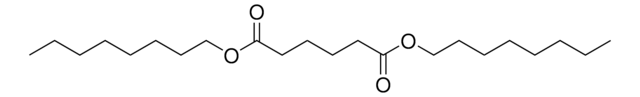

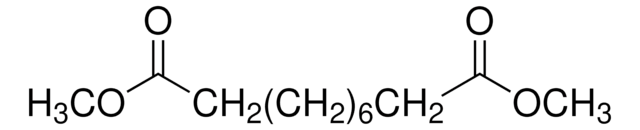

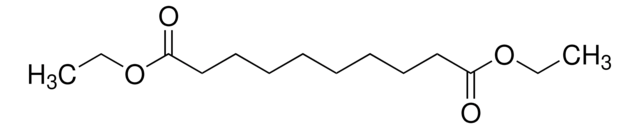

Linear Formula:

[-(CH2)4CO2(CH2)3CH3]2

CAS Number:

Molecular Weight:

314.46

Beilstein:

1798308

EC Number:

MDL number:

UNSPSC 코드:

12162002

PubChem Substance ID:

NACRES:

NA.23

추천 제품

Grade

technical grade

양식

liquid

refractive index

n20/D 1.441 (lit.)

bp

178-179 °C/3 mmHg (lit.)

solubility

hexane, toluene, ethanol and acetone: soluble

water and propylene glycol: insoluble

density

0.936 g/mL at 25 °C (lit.)

SMILES string

CCCCOC(=O)CCCCCCCCC(=O)OCCCC

InChI

1S/C18H34O4/c1-3-5-15-21-17(19)13-11-9-7-8-10-12-14-18(20)22-16-6-4-2/h3-16H2,1-2H3

InChI key

PYGXAGIECVVIOZ-UHFFFAOYSA-N

유사한 제품을 찾으십니까? 방문 제품 비교 안내

일반 설명

Dibutyl sebacate(DBS) is a lipophilic dibutyl ester that can be used as a plasticizer with low solubility in water.

애플리케이션

DBS can be used as a plasticizer for the formation of ethylcellulose based coating membranes which can be potentially used in drug delivery systems. It may also be used as a plasticizer during the fabrication of electronic artificial tongue sensors for analyzing the intensity of olive oils.

Storage Class Code

10 - Combustible liquids

WGK

WGK 1

Flash Point (°F)

366.8 °F - open cup

Flash Point (°C)

186 °C - open cup

개인 보호 장비

Eyeshields, Gloves, type ABEK (EN14387) respirator filter

이미 열람한 고객

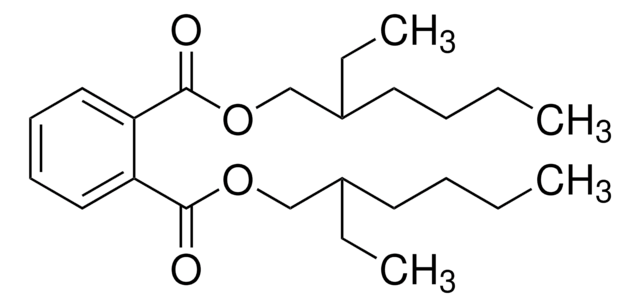

GC method for determining polyadipate plasticizers in foods: transesterification to dibutyl adipate, conversion to migrating polyadipate.

Biedermann M and Grob K

Chromatographia, 64(9-10), 543-552 (2006)

Sensory intensity assessment of olive oils using an electronic tongue.

Veloso ACA, et al.

Talanta, 146(3), 585-593 (2016)

Physico-mechanical analysis of free ethylcellulose films plasticized with incremental weight percents of dibutyl sebacate.

Kangarlou S and Haririan I

Iranian Journal of Pharmaceutical Sciences, 3(3), 135-142 (2007)

Marilena Saviano et al.

International journal of pharmaceutics, 561, 1-8 (2019-03-01)

Fused deposition modeling by 3D-printing is a rapid technique for the production of personalized drug dosage forms. One of the most delicate step of the whole process is the drug loading onto the thermoplastic polymer to obtain the drug-loaded filament

E Oh et al.

International journal of pharmaceutics, 188(2), 203-219 (1999-10-16)

The surface free energy parameters of ethylcellulose (EC) films were determined using the Lifshitz-van der Waals/acid-base approach and the influence of plasticizers on their surface energetics was assessed. Films were prepared by dip-coating glass slides in organic solvents containing EC

자사의 과학자팀은 생명 과학, 재료 과학, 화학 합성, 크로마토그래피, 분석 및 기타 많은 영역을 포함한 모든 과학 분야에 경험이 있습니다..

고객지원팀으로 연락바랍니다.