추천 제품

설명

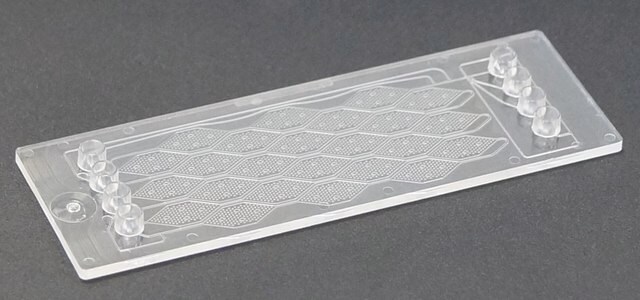

Microfludic chip x1

유사한 제품을 찾으십니까? 방문 제품 비교 안내

애플리케이션

Microfluidic generation of droplets can produce highly monodispersed droplets with high frequency (up to hundreds of kHz). Interest in droplet-based microfluidic systems has grown substantially, because microfluidics offers the ability to handle very small volumes (μl to fl) of fluids, provides better mixing, encapsulation, sorting, and sensing. Microfluidics can be used for high throughput experimentation. Microfluidic-based droplets have many applications, including micro and nanoparticle synthesis and chemical analysis. Highly controlled droplet production also makes single cell analysis, or drug testing possible.

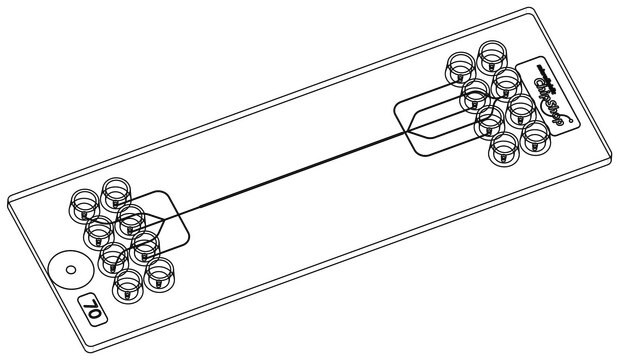

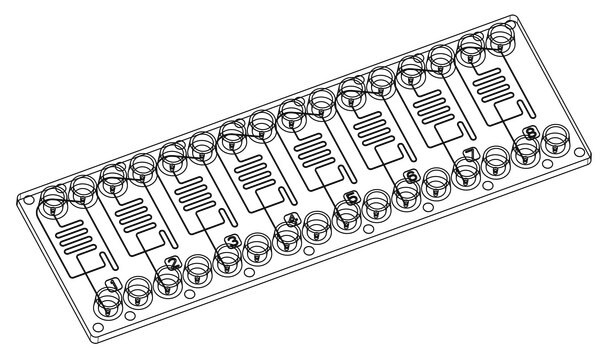

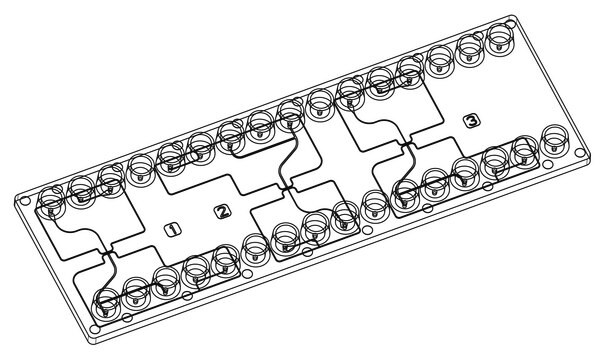

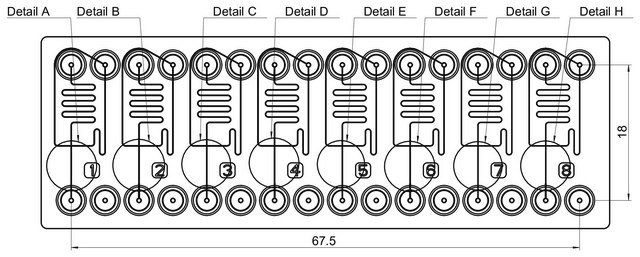

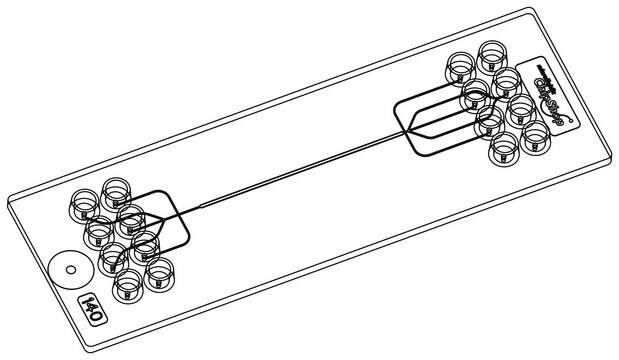

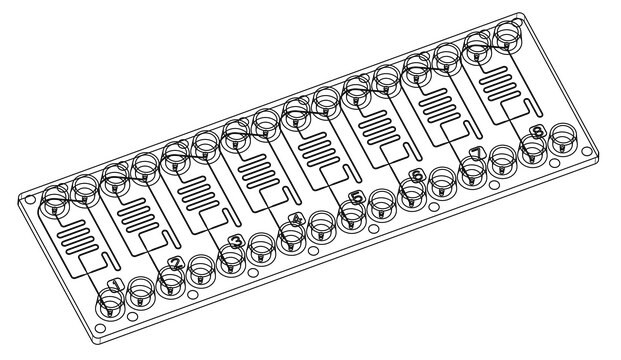

Droplet generator chip - One channel design, Fluidic 162, COC is made of COC (Cyclic olefin copolymer ), it features a double channel crossing in the droplet generation region and one droplet collection channel. Like most droplet generators with a double cross geometry, Fluidic 162 can also be used for single cross experiments by simply not connecting respective channels but closing their interfaces with plugs. With a nozzle size of 70 μm droplet sizes between 80 μm (∼260 pl) and 210 μm diameter can be realized. A constant droplet size can be generated in various flow speeds by preserving the oil to aqueous phase ratio. By increasing the oil phase flow rate at a constant aqueous flow rate, the droplet size can be varied.

Droplet generator chip - One channel design, Fluidic 162, COC is made of COC (Cyclic olefin copolymer ), it features a double channel crossing in the droplet generation region and one droplet collection channel. Like most droplet generators with a double cross geometry, Fluidic 162 can also be used for single cross experiments by simply not connecting respective channels but closing their interfaces with plugs. With a nozzle size of 70 μm droplet sizes between 80 μm (∼260 pl) and 210 μm diameter can be realized. A constant droplet size can be generated in various flow speeds by preserving the oil to aqueous phase ratio. By increasing the oil phase flow rate at a constant aqueous flow rate, the droplet size can be varied.

가장 최신 버전 중 하나를 선택하세요:

Recent advances of controlled drug delivery using microfluidic platforms.

Li X, et al.

Advanced Drug Delivery Reviews, 128, 3-28 (2018)

Microfluidic-assisted fabrication of carriers for controlled drug delivery.

Santos H A, et al.

Lab on a chip, 17, 1856-1883 (2017)

Sharma T Sanjay et al.

Advanced drug delivery reviews, 128, 3-28 (2017-09-19)

Conventional systematically-administered drugs distribute evenly throughout the body, get degraded and excreted rapidly while crossing many biological barriers, leaving minimum amounts of the drugs at pathological sites. Controlled drug delivery aims to deliver drugs to the target sites at desired

Dongfei Liu et al.

Lab on a chip, 17(11), 1856-1883 (2017-05-10)

The microfluidic technique has brought unique opportunities toward the full control over the production processes for drug delivery carriers, owing to the miniaturisation of the fluidic environment. In comparison to the conventional batch methods, the microfluidic setup provides a range

자사의 과학자팀은 생명 과학, 재료 과학, 화학 합성, 크로마토그래피, 분석 및 기타 많은 영역을 포함한 모든 과학 분야에 경험이 있습니다..

고객지원팀으로 연락바랍니다.