추천 제품

Quality Level

양식

lyophilized powder

불순물

<10 CFU/g Bioburden

<100 EU/g Endotoxin

색상

white to pale yellow

저장 온도

2-8°C

애플리케이션

This product is low endotoxin version alginate, it is lyophilized powder and ready to be used in biomedical applications.

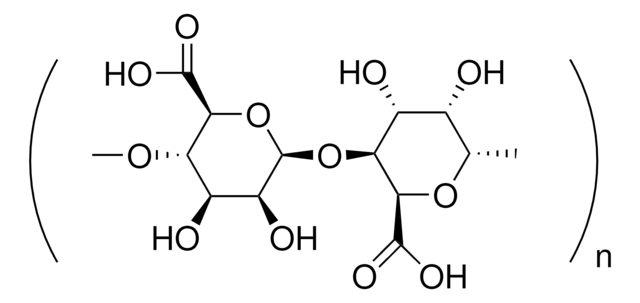

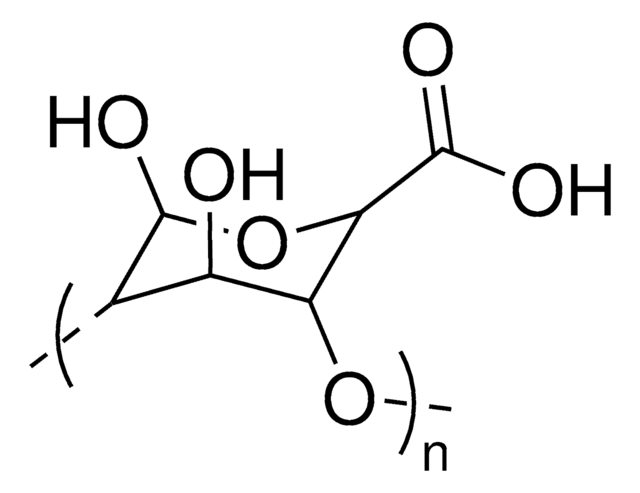

Alginate is an anionic polysaccharide that is widely used in pharmaceutical and biomedical applications due to its non-animal origin, low toxicity, biocompatibility, and biodegradability. Alginate hydrogels are commonly used to fabricate tissue engineering scaffolds, bioinks for 3D bioprinting, and nanocarriers for drug & gene delivery. Alginate is commonly crosslinked into a hydrogel via ionic-crosslinking with divalent cations (e.g., Ca2+).

Alginate is an anionic polysaccharide that is widely used in pharmaceutical and biomedical applications due to its non-animal origin, low toxicity, biocompatibility, and biodegradability. Alginate hydrogels are commonly used to fabricate tissue engineering scaffolds, bioinks for 3D bioprinting, and nanocarriers for drug & gene delivery. Alginate is commonly crosslinked into a hydrogel via ionic-crosslinking with divalent cations (e.g., Ca2+).

포장

500mg in glass bottle

Storage Class Code

13 - Non Combustible Solids

WGK

WGK 2

Flash Point (°F)

Not applicable

Flash Point (°C)

Not applicable

가장 최신 버전 중 하나를 선택하세요:

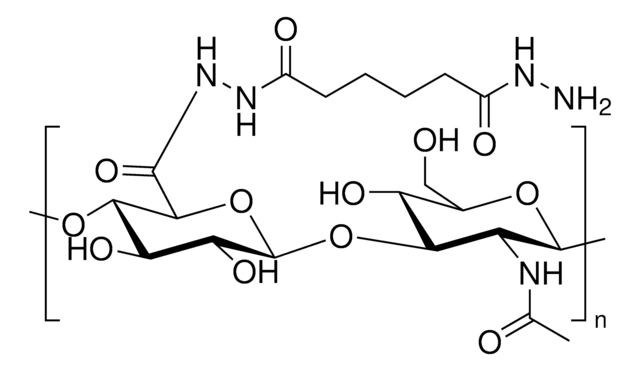

Jia Jia et al.

Acta biomaterialia, 10(10), 4323-4331 (2014-07-08)

Recent advances in three-dimensional (3-D) printing offer an excellent opportunity to address critical challenges faced by current tissue engineering approaches. Alginate hydrogels have been used extensively as bioinks for 3-D bioprinting. However, most previous research has focused on native alginates

Kuen Yong Lee et al.

Progress in polymer science, 37(1), 106-126 (2011-11-30)

Alginate is a biomaterial that has found numerous applications in biomedical science and engineering due to its favorable properties, including biocompatibility and ease of gelation. Alginate hydrogels have been particularly attractive in wound healing, drug delivery, and tissue engineering applications

Tarun Agarwal et al.

ACS applied materials & interfaces, 8(47), 32132-32145 (2016-12-10)

Success of bone tissue engineering (BTE) relies on the osteogenic microarchitecture of the biopolymeric scaffold and appropriate spatiotemporal distribution of therapeutic molecules (growth factors and drugs) inside it. However, the existing technologies have failed to address both the issues together.

Eneko Axpe et al.

International journal of molecular sciences, 17(12) (2016-11-30)

Three-dimensional (3D) bioprinting is on the cusp of permitting the direct fabrication of artificial living tissue. Multicellular building blocks (bioinks) are dispensed layer by layer and scaled for the target construct. However, only a few materials are able to fulfill

자사의 과학자팀은 생명 과학, 재료 과학, 화학 합성, 크로마토그래피, 분석 및 기타 많은 영역을 포함한 모든 과학 분야에 경험이 있습니다..

고객지원팀으로 연락바랍니다.