추천 제품

분자량

average Mn ~550

Quality Level

refractive index

n20/D 1.405

점도

~25 cSt

bp

182 °C

density

0.95 g/mL at 25 °C

SMILES string

C[Si](C)(O)O

InChI

1S/C2H8O2Si/c1-5(2,3)4/h3-4H,1-2H3

InChI key

XCLIHDJZGPCUBT-UHFFFAOYSA-N

유사한 제품을 찾으십니까? 방문 제품 비교 안내

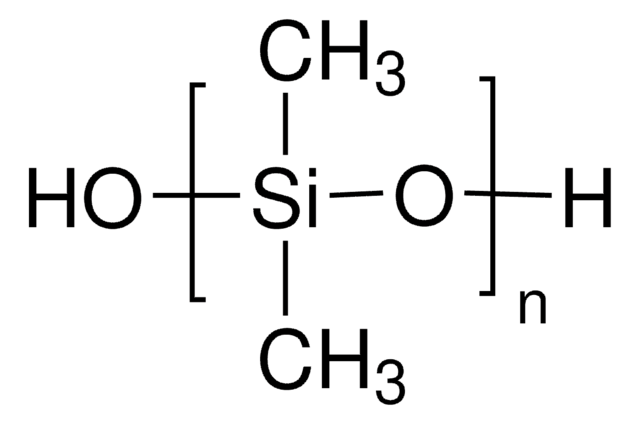

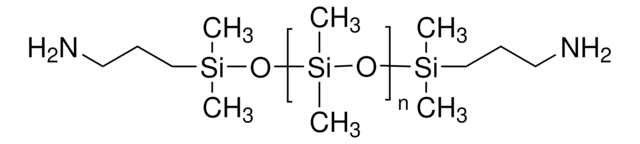

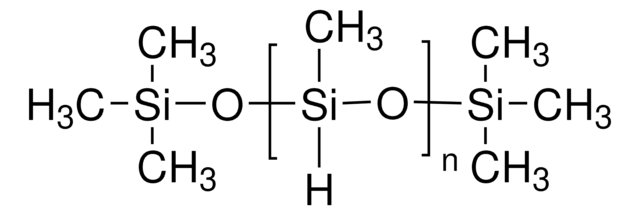

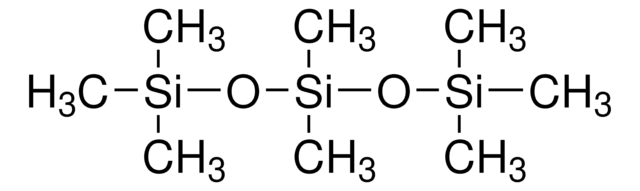

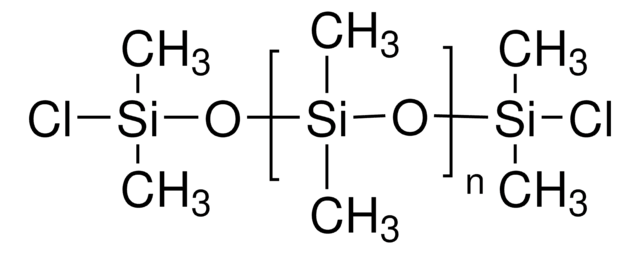

일반 설명

Polydimethylsiloxane(PDMS) is a silicon-basedorganic polymer that is nontoxic, optically clear, inert, and inflammablematerial. It is widely used in heat-resistant lubricants, fire retardants,medical devices, and cosmetics. Polydimethylsiloxane is hydrophobic,cytocompatible, and viscoelastic which can be used to prepare water-repellentcoatings in the textile industry.

애플리케이션

PDMS can be used as a precursor in the synthesis of poly(dimethylsiloxane-urethane) elastomers with improved mechanical and thermal properties.

PDMS is a material of choice for ophthalmic applications due to its high mechanical strength, transparency, and oxygen permeability. It can be used as a prepolymer to prepare a glucose permeable interpenetrating network of PDMS and poly (N-isopropyl acrylamide (PNIPAAM). These networks can be used in ophthalmic applications.

PDMS can also be used to synthesize fire and heat-resistant polyurethane-PDMS hybrids. The addition of PDMS provides low flammability and thermal stabilization to polyurethane under pyrolytic conditions.

PDMS is used as an additive to prepare TEOS-based stone protective hybrid crack-free xerogels. The addition of PDMS accelerates the gelling process and helps to achieve effective stone protection.

PDMS is a material of choice for ophthalmic applications due to its high mechanical strength, transparency, and oxygen permeability. It can be used as a prepolymer to prepare a glucose permeable interpenetrating network of PDMS and poly (N-isopropyl acrylamide (PNIPAAM). These networks can be used in ophthalmic applications.

PDMS can also be used to synthesize fire and heat-resistant polyurethane-PDMS hybrids. The addition of PDMS provides low flammability and thermal stabilization to polyurethane under pyrolytic conditions.

PDMS is used as an additive to prepare TEOS-based stone protective hybrid crack-free xerogels. The addition of PDMS accelerates the gelling process and helps to achieve effective stone protection.

Storage Class Code

10 - Combustible liquids

WGK

WGK 1

Flash Point (°F)

Not applicable

Flash Point (°C)

Not applicable

개인 보호 장비

Eyeshields, Gloves, multi-purpose combination respirator cartridge (US)

이미 열람한 고객

L Liu et al.

Biomaterials, 26(3), 233-244 (2004-07-21)

Poly (dimethyl siloxane) (PDMS) has been widely used as a biomaterial in ophthalmic and other applications due to its good compatibility, high mechanical strength, excellent oxygen permeability and transparency. However, for use as an artificial cornea, contact lens and in

문서

Advances in the area of soft optoelectronics, with a focus on the development of organic optoelectronic devices on shape memory polymers (SMP) is discussed.

관련 콘텐츠

We offer PDMS surface modification kit which allows for durable hydrophilization of various polydimethylsiloxane (PDMS) surfaces.

Global Trade Item Number

| SKU | GTIN |

|---|---|

| 481939-100ML | 4061832389097 |

| 481939-500ML | 4061832389103 |

자사의 과학자팀은 생명 과학, 재료 과학, 화학 합성, 크로마토그래피, 분석 및 기타 많은 영역을 포함한 모든 과학 분야에 경험이 있습니다..

고객지원팀으로 연락바랍니다.