P2B100C01

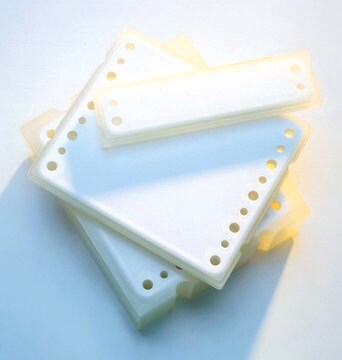

Pellicon® 2 Mini Ultrafiltration Biomax® Module

filtration area 0.1 m2, NMWCO 100 kDa

Synonym(s):

Pellicon® 2 Mini Ultrafiltration Module Biomax-100 C 0.1 m2

About This Item

Recommended Products

material

polyethersulfone

polypropylene screen

polyurethane adhesive

Quality Level

manufacturer/tradename

Pellicon®

parameter

0.33 bar max. transmembrane pressure (5 psig) (reverse)

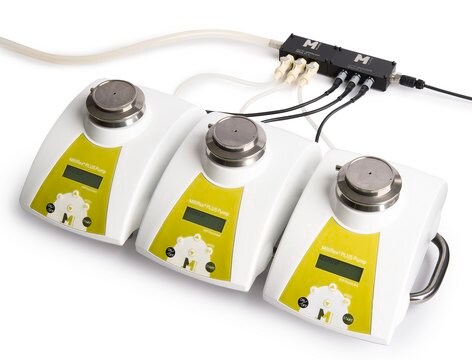

5-35 L/min recirculation rate at 0.4 bar (6 psi)

7 bar max. transmembrane pressure (100 psig) at 30 °C (forward)

technique(s)

analytical sample preparation: suitable

protein purification: suitable

H

1.5 cm (0.6 in.)

L

21 cm (8.3 in.)

W

5.6 cm (2.2 in.)

filtration area

0.1 m2

membrane nominal area

0.1 m2

gravimetric extractables

≤1500 mg/m2

matrix

Biomax®

pore size

100 kDa NMWCO

pH

1-14

Looking for similar products? Visit Product Comparison Guide

General description

Millipore′s BIOMAX 100 polyethersulfone membrane has void-free structures that guard against leakage of solutes through microdefects normally associated with voids beneath the thin skins of conventional UF membranes. These void-free membranes are more permeable, resulting in high-flux with equivalent or superior product retention. These void-free membranes provide the advantages of fast, high yield processing and smaller systems.

The Pellicon® 2 Mini Ultrafiltration BIOMAX Module feature a filtration area of 0.1 m2 with a pore size of 100 kDa NMWCO.

Application

- Protein solutions

- Polysaccharide solutions

- Virus suspensions

Harvest, washing or clarification of:

- Cell cultures and lysates

- Colloidal suspensions

- Viral cultures

Features and Benefits

- Type C screen (coarse screen)

- Leading-edge void- free membranes to match virtually any separation challenge

- Short flow path for higher flux and higher resolution separation capability

- Choice of flow channel configuration providing process optimization capability

- Predictable, fast, scale-up

- True linear scalability from laboratory size modules to industrial assemblies for processing thousands of liters

- Brings higher resolution, improved yields and superior back-pressure resistance

- Ultracel membranes are composite membranes cast on a microporous substrate for defect-free membranes with superior

Other Notes

Analysis Note

Legal Information

Storage Class Code

10 - Combustible liquids

WGK

WGK 2

Regulatory Listings

Regulatory Listings are mainly provided for chemical products. Only limited information can be provided here for non-chemical products. No entry means none of the components are listed. It is the user’s obligation to ensure the safe and legal use of the product.

ISHL Notified Names

Substances Subject to be Notified Names

JAN Code

P2B100C01:

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Related Content

A relatively templated manufacturing process can be used to produce live vector vaccines. Challenges exist, however, and include yield loss due to sterile filtration, vector aggregation and scaling adherent cultures. Learn all about this core platform technology and how expertise—empowered by collaboration— can overcome manufacturing challenges.

Manufacturing viral vaccines is complex and there is no templated approach. Each process must be tailored to the shape, size, nature, physico-chemical behavior, stability, and host specificity of the virus. Learn all about this core platform technology and how expertise—empowered by collaboration— can overcome manufacturing challenges.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service