Key Documents

Safety Information

1.01695

Benzonase®

suitable for biopharmaceutical production EMPROVE® bio

Pharma Manufacturing

Synonym(s):

Endonuclease from Serratia marcescens

About This Item

Recommended Products

biological source

Serratia marcescens

Quality Level

recombinant

expressed in E. coli

product line

EMPROVE® Bio

Assay

≥99% (SDS-PAGE)

form

buffered aqueous glycerol solution

concentration

≥250 units/μL

pH

8.0 (25 °C in H2O)

application(s)

pharma/biopharma processes

shipped in

dry ice

storage temp.

-10 to -25°C

Looking for similar products? Visit Product Comparison Guide

General description

Benzonase® endonuclease is the smart solution for DNA removal in viral vaccine and viral vector production and has proven its value for over 30 years. Balancing efficiency and regulatory compliance by delivering reliability and high-quality due manufacturing under good manufacturing practices (GMP ICH Q7). Our extensive documentation packages of Emprove® dossiers and the availability of a FDA Drug Master File type II, supports you in filing your vaccine manufacturing process to the authorities.

M-Clarity Program

As part of our EMPROVE® Program, our raw materials are offered with EMPROVE® Dossiers which provide comprehensive, up-to-date documentation to help you navigate regulatory challenges, manage risks, and improve your manufacturing processes.

Our comprehensive portfolio of downstream process chemicals not only provides biopharmaceutical manufacturers with high-quality raw materials for production of classical and novel therapies, but also helps them get to market faster and simplify regulatory challenges. Ranging from non-GMP grades for low-risk application, to IPEC-PQG GMP for higher-risk applications, we have products covering all your manufacturing needs.

Application

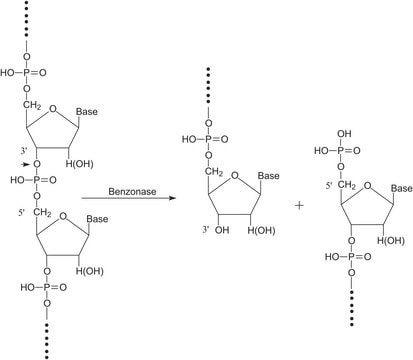

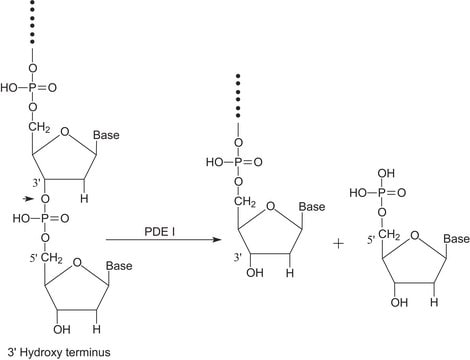

Biochem/physiol Actions

Legal Information

also commonly purchased with this product

related product

Storage Class Code

10 - Combustible liquids

WGK

WGK 1

Regulatory Listings

Regulatory Listings are mainly provided for chemical products. Only limited information can be provided here for non-chemical products. No entry means none of the components are listed. It is the user’s obligation to ensure the safe and legal use of the product.

JAN Code

1016958001:

1016950004:

MX11016950001:

1016950001:

1016950003:

1016950000:

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Related Content

A relatively templated manufacturing process can be used to produce live vector vaccines. Challenges exist, however, and include yield loss due to sterile filtration, vector aggregation and scaling adherent cultures. Learn all about this core platform technology and how expertise—empowered by collaboration— can overcome manufacturing challenges.

Manufacturing viral vaccines is complex and there is no templated approach. Each process must be tailored to the shape, size, nature, physico-chemical behavior, stability, and host specificity of the virus. Learn all about this core platform technology and how expertise—empowered by collaboration— can overcome manufacturing challenges.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service