529257

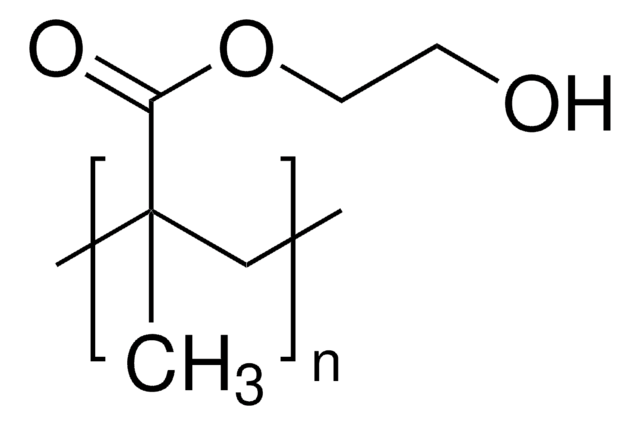

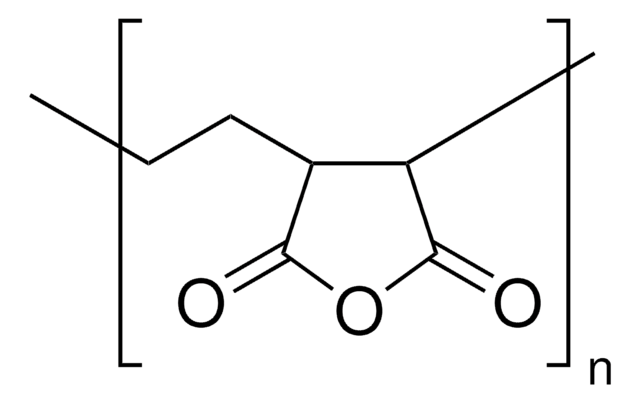

Poly(2-hydroxyethyl methacrylate)

average Mv 1,000,000

Synonym(s):

Poly(2-HEMA), Poly-HEMA

About This Item

Recommended Products

form

crystals

Quality Level

mol wt

average Mv 1,000,000

density

1.15 g/mL at 25 °C (lit.)

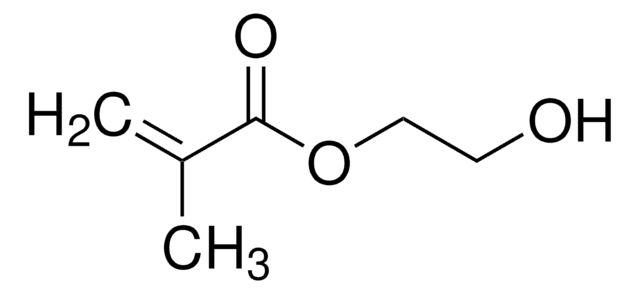

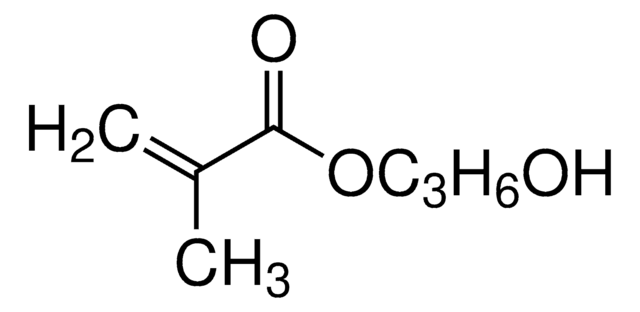

SMILES string

CC(=C)C(=O)OCCO

InChI

1S/C6H10O3/c1-5(2)6(8)9-4-3-7/h7H,1,3-4H2,2H3

InChI key

WOBHKFSMXKNTIM-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

Physical form

Storage Class Code

11 - Combustible Solids

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Personal Protective Equipment

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

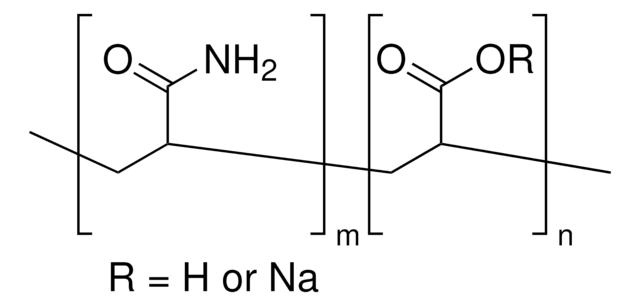

Customers Also Viewed

Articles

Professor Shrike Zhang (Harvard Medical School, USA) discusses advances in 3D-bioprinted tissue models for in vitro drug testing, reviews bioink selections, and provides application examples of 3D bioprinting in tissue model biofabrication.

Professor Shrike Zhang (Harvard Medical School, USA) discusses advances in 3D-bioprinted tissue models for in vitro drug testing, reviews bioink selections, and provides application examples of 3D bioprinting in tissue model biofabrication.

Self-assembled monolayers (SAMs) have attracted enormous interest for a wide variety of applications in micro- and nano-technology. In this article, we compare the benefits of three different classes of SAM systems (alkylthiolates on gold.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service