C1184

Cellulase from Aspergillus niger

powder, ≥0.3 units/mg solid

Synonym(s):

1,4-(1,3:1,4)-β-D-Glucan 4-glucanohydrolase

About This Item

Recommended Products

form

powder

Quality Level

specific activity

≥0.3 units/mg solid

greener alternative product characteristics

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

greener alternative category

, Enabling

storage temp.

2-8°C

Looking for similar products? Visit Product Comparison Guide

Related Categories

General description

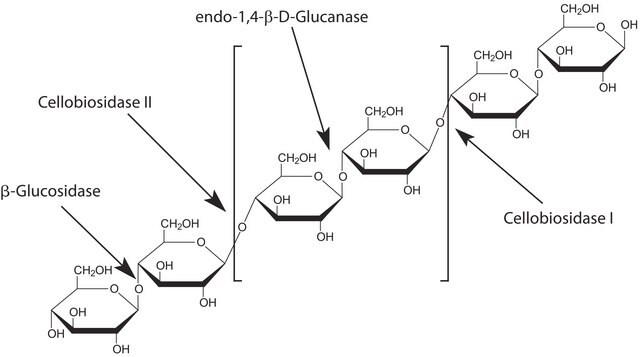

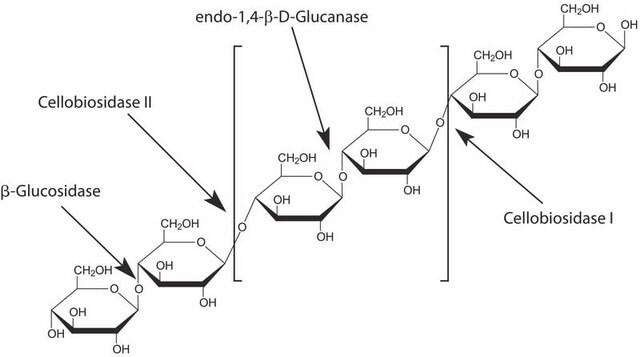

Cellulase belongs to the family of glycoside hydrolase, which is secreted by various cellulolytic microorganisms.

Application

Biochem/physiol Actions

Unit Definition

Other Notes

substrate

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Resp. Sens. 1

Storage Class Code

11 - Combustible Solids

WGK

WGK 1

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Personal Protective Equipment

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service