8.00609

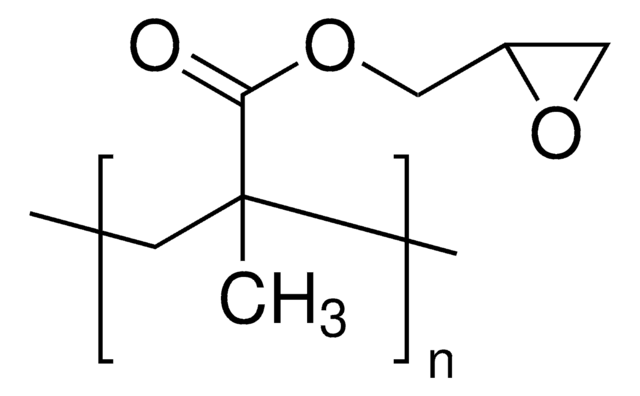

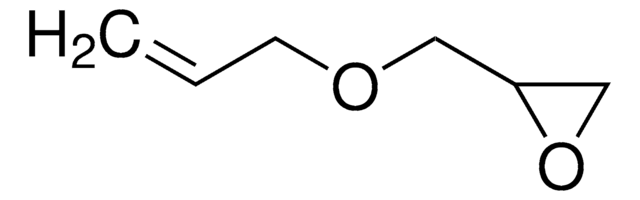

2,3-Epoxypropyl methacrylate

Technipur®, for synthesis

Synonym(s):

Glycidyl methacrylate, 2-((Methacryloxy)methyl)oxirane, 2,3-Epoxypropyl methacrylate, Methacrylic acid 2,3-epoxypropyl ester

About This Item

Recommended Products

grade

for synthesis

Quality Level

vapor pressure

4.2 hPa ( 25 °C)

refractive index

n20/D 1.449 (lit.)

bp

189 °C (lit.)

mp

<-60 °C

density

1.042 g/mL at 25 °C (lit.)

1.07 g/cm3 at 25 °C

SMILES string

CC(=C)C(=O)OCC1CO1

InChI

1S/C7H10O3/c1-5(2)7(8)10-4-6-3-9-6/h6H,1,3-4H2,2H3

InChI key

VOZRXNHHFUQHIL-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

General description

Application

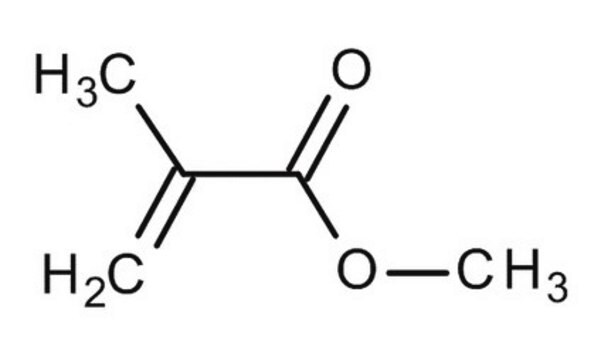

It is also used to prepare poly(n-butyl methacrylate-co-glycidyl methacrylate) copolymers, which find applications in adhesives, surface coatings, and electrical devices in various polymeric industries. The presence of epoxy groups and flexible butyl groups in epoxy resin-modified copolymers increases its mechanical properties, impact strength, and fracture elongation.

Legal Information

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Acute Tox. 3 Dermal - Acute Tox. 4 Oral - Carc. 1B - Eye Dam. 1 - Muta. 2 - Repr. 1B - Skin Corr. 1C - Skin Sens. 1 - STOT RE 1 - STOT SE 3

Target Organs

Respiratory system

Storage Class Code

6.1C - Combustible, acute toxic Cat.3 / toxic compounds or compounds which causing chronic effects

WGK

WGK 3

Flash Point(F)

168.8 °F - closed cup

Flash Point(C)

76 °C - closed cup

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service