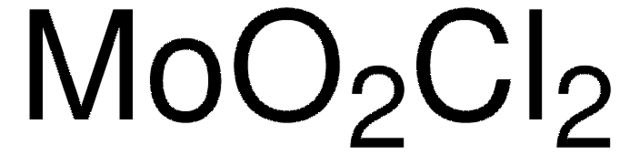

203815

Molybdenum(VI) oxide

99.97% trace metals basis

Synonym(s):

Molybdenum trioxide

About This Item

Recommended Products

Quality Level

Assay

99.97% trace metals basis

form

powder

mp

795 °C (lit.)

application(s)

battery manufacturing

SMILES string

O=[Mo](=O)=O

InChI

1S/Mo.3O

InChI key

JKQOBWVOAYFWKG-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

General description

Application

Signal Word

Warning

Hazard Statements

Precautionary Statements

Hazard Classifications

Carc. 2 - Eye Irrit. 2 - STOT SE 3

Target Organs

Respiratory system

Storage Class Code

11 - Combustible Solids

WGK

WGK 1

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Personal Protective Equipment

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Advances in materials have often been led by the development of new synthetic methods that provide control over size, morphology and structure.

Advances in materials have often been led by the development of new synthetic methods that provide control over size, morphology and structure. The preparation of materials in a scalable and continuous manner is critical when development moves beyond lab-scale quantities.

The production of hydrogen by catalytic water splitting is important for a wide range of industries including renewable energy petroleum refining and for the production of methanol and ammonia in the chemical industry.

Professor Chen (Nankai University, China) and his team explain the strategies behind their recent record-breaking organic solar cells, reaching a power conversion efficiency of 17.3%.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service