918571

3D Printable Yttria-stabilized Zirconium(IV) Oxide Ink

Synonyme(s) :

3D printable ceramic ink, 3Y-ZrO2 ink, YSZ ink, Yttria stabilized zirconia ink, Yttrium stabilized zirconium oxide ink

About This Item

Produits recommandés

Description

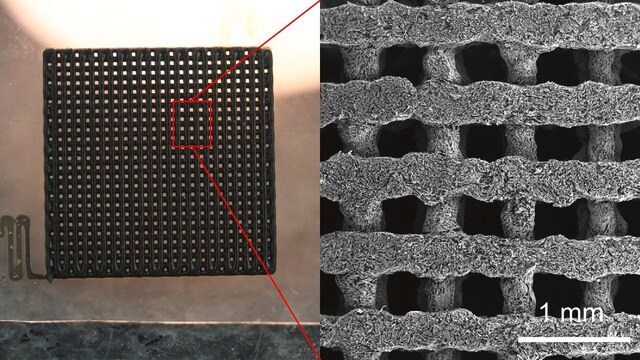

Printing methods compatible with: Direct-Ink-Writing 3D printing

Niveau de qualité

Forme

paste

Caractéristiques du produit alternatif plus écologique

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

Concentration

70 wt. % (Yttria stabilized zirconia)

Couleur

white

Taille des particules

120 nm

Viscosité

2-25 Pa.s (25 °C at shear rate of 100 s-1)

Autre catégorie plus écologique

Température de stockage

2-8°C

Description générale

Application

Attention

- Store in an airtight sealed container in refrigerator.

- Avoid exposure to heat.

- Add the thermal initiator (product No.479896) to 0.3wt% of the total 3Y-ZrO2/PEGDA ink mass, and mix well before usage.

Notes préparatoires

Direct-Ink-Writing (DIW) Notes:

- Syringe Nozzle sizes ranging from 250 μm − 800 μm can be used.

- Initial pressure for DIW printing ranges from 12-18 psi, depending on nozzle diameter used.

Post Processing of DIW printed parts:

- Curing @ 110°C for 12-16 hours.

- Sintering using the following sequence:

Ramp to 300°C @ 1°C/min. Hold for 4 hours.

Ramp to 400°C @ 1°C/min. Hold for 2 hours.

Ramp to 800°C @ 2°C/min. Hold for 4 hours.

Ramp to 1090°C @ 2°C/min. Hold for 15 hours.

Ramp down to 50°C @ 2°C/min.

Stockage et stabilité

Mention d'avertissement

Danger

Mentions de danger

Conseils de prudence

Classification des risques

Eye Dam. 1 - Skin Irrit. 2 - Skin Sens. 1 - STOT SE 3

Organes cibles

Respiratory system

Code de la classe de stockage

10 - Combustible liquids

Classe de danger pour l'eau (WGK)

WGK 3

Faites votre choix parmi les versions les plus récentes :

Certificats d'analyse (COA)

Désolés, nous n'avons pas de COA pour ce produit disponible en ligne pour le moment.

Si vous avez besoin d'assistance, veuillez contacter Service Clients

Déjà en possession de ce produit ?

Retrouvez la documentation relative aux produits que vous avez récemment achetés dans la Bibliothèque de documents.

Articles

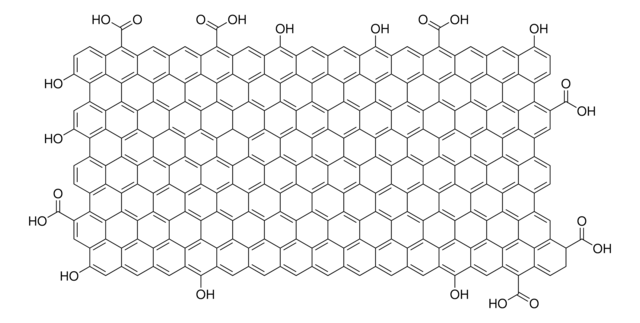

Partnering additive manufacturing (3D printing) with functional nanomaterial-based inks has the potential to push the properties and performance of advanced materials beyond previous capabilities. This is particularly true in energy and environmental applications.

Notre équipe de scientifiques dispose d'une expérience dans tous les secteurs de la recherche, notamment en sciences de la vie, science des matériaux, synthèse chimique, chromatographie, analyse et dans de nombreux autres domaines..

Contacter notre Service technique