761036

SYLGARD® 184

10 g clip-pack

Synonyme(s) :

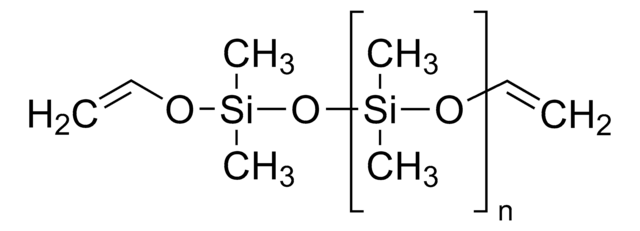

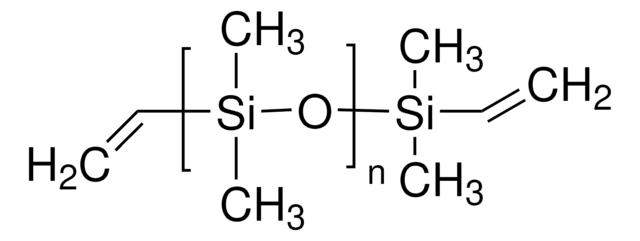

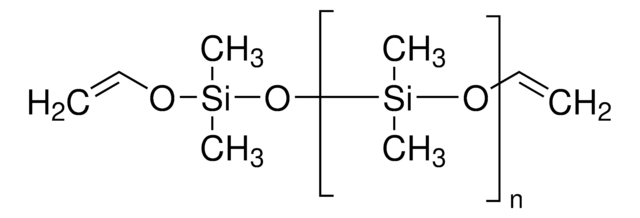

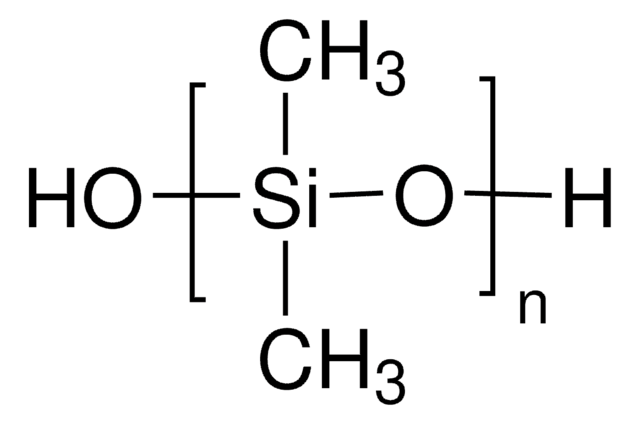

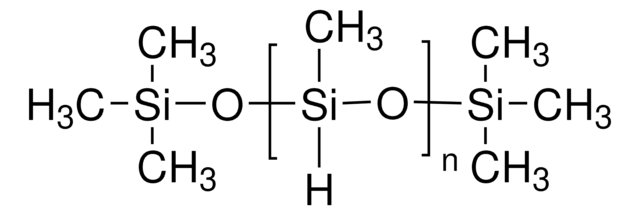

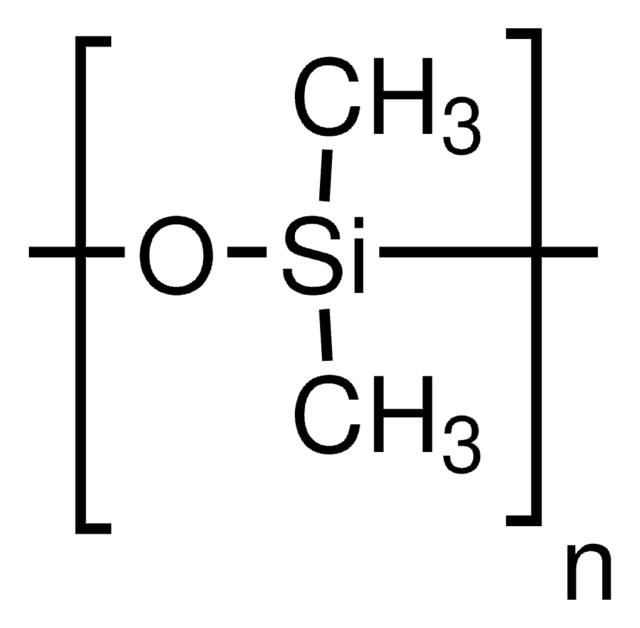

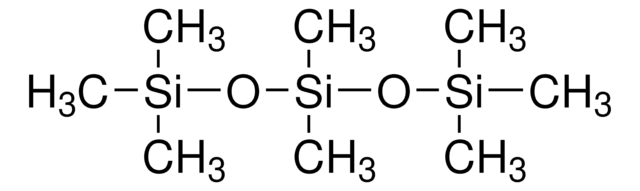

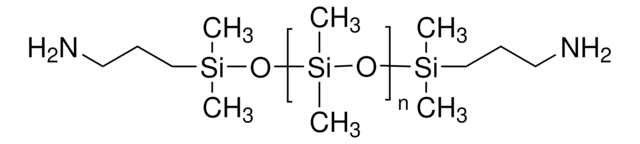

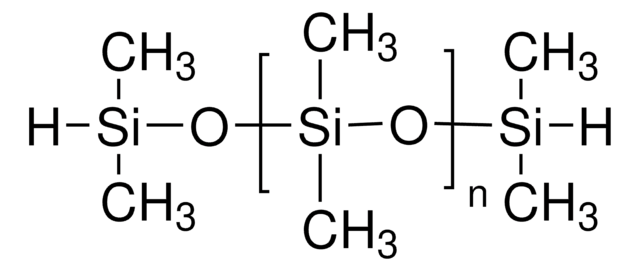

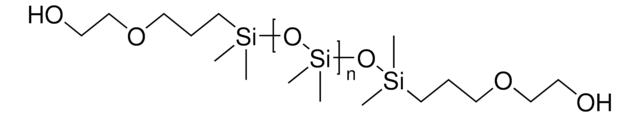

Curing agent, Polydimethylsiloxane, Silicone, Vinyl-terminated PDMS

About This Item

Produits recommandés

Niveau de qualité

Description

Dielectric shore 43

Volume resistivity 2.9E+14 ohm*cm

Forme

liquid

Indice de réfraction

n/1554 1.3997

n/1321 1.4028

n/589 1.4118

n/632.8 1.4225

Vous recherchez des produits similaires ? Visite Guide de comparaison des produits

Description générale

Application

Conditionnement

SYLGARD 184 Silicone Elastomer Kit is comprised of Base/Curing Agent to be mixed in a 10 (base) :1 (curing agent) ratio by weight for manual mixing.

Notes préparatoires

PROCESSING/CURING - Thoroughly mixed the silicone encapsulant may be poured/dispensed directly into the container in which it is to be cured. Care should be taken to minimize air entrapment. When practical, pouring/dispensing should be done under vacuum, particularly if the component being potted or encapsulated has many small voids. If this technique cannot be used, the unit should be evacuated after the silicone encapsulant has been poured/ dispensed. Dow silicone encapsulants may be either room temperature (25°C/77°F) or heat cured. Room temperature cure encapsulants may also be heat accelerated for faster cure. Ideal cure conditions for each product are given in the product selection table.

POT LIFE AND CURE RATE - Cure reaction begins with the mixing process. Initially, cure is evidenced by a gradual increase in viscosity, followed by gelation and conversion to a solid elastomer. Pot life is defined as the time required for viscosity to double after base and curing agent are mixed and is highly temperature and application dependent. Please refer to the data table.

USEFUL TEMPERATURE RANGES - For most uses, silicone elastomers should be operational over a temperature range of -45 to 200°C (-49 to 392°F) for long periods of time. However, at both the low and high temperature ends of the spectrum, behavior of the materials and performance in particular applications can become more complex and require additional considerations and should be adequately tested for the particular end-use environment. For low temperature performance, thermal cycling to conditions such as -55°C (-67°F) may be possible, but performance should be verified for your parts or assemblies. Factors that may influence performance are configuration and stress sensitivity of components, cooling rates and hold times, and prior temperature history. At the high-temperature end, the durability of the cured silicone elastomer is time and temperature dependent. As expected, the higher the temperature, the shorter the time the material will remain useable.

COMPATIBILITY - Certain materials, chemicals, curing agents and plasticizers can inhibit the cure of addition cure gels. Most notable of these include: Organotin and other organometallic compounds, silicone rubber containing organotin catalyst, sulfur, polysulfides, polysulfones or other sulfur containing materials, unsaturated hydrocarbon plasticizers, and some solder flux residues. If a substrate or material is questionable with respect to potentially causing inhibition of cure, it is recommended that a small scale compatibility test be run to ascertain suitability in a given application. The presence of liquid or uncured product at the interface between the questionable substrate and the cured gel indicates incompatibility and inhibition of cure.

Informations légales

Mention d'avertissement

Warning

Mentions de danger

Conseils de prudence

Classification des risques

Eye Irrit. 2 - Skin Irrit. 2 - STOT SE 3

Organes cibles

Respiratory system

Code de la classe de stockage

10 - Combustible liquids

Faites votre choix parmi les versions les plus récentes :

Déjà en possession de ce produit ?

Retrouvez la documentation relative aux produits que vous avez récemment achetés dans la Bibliothèque de documents.

Les clients ont également consulté

Articles

Dr. Tan and researcher introduce recent trends in Self-healing Soft Electronic Materials and Devices. The emergence of smart, functional SHPs will be highly beneficial to the advancement of the next-generation self-healing soft electronic devices. Autonomously self-healing devices could help to minimize the need for repair or replacement of electronics and machines, potentially reducing the cost of materials and reducing electronic waste.

Advances in the area of soft optoelectronics, with a focus on the development of organic optoelectronic devices on shape memory polymers (SMP) is discussed.

Contenu apparenté

We offer PDMS surface modification kit which allows for durable hydrophilization of various polydimethylsiloxane (PDMS) surfaces.

Notre équipe de scientifiques dispose d'une expérience dans tous les secteurs de la recherche, notamment en sciences de la vie, science des matériaux, synthèse chimique, chromatographie, analyse et dans de nombreux autres domaines..

Contacter notre Service technique