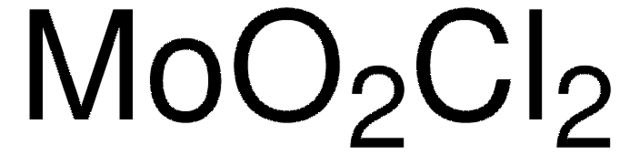

203815

Molybdenum(VI) oxide

99.97% trace metals basis

Synonyme(s) :

Molybdenum trioxide

About This Item

Produits recommandés

Pureté

99.97% trace metals basis

Forme

powder

Pf

795 °C (lit.)

Application(s)

battery manufacturing

Chaîne SMILES

O=[Mo](=O)=O

InChI

1S/Mo.3O

Clé InChI

JKQOBWVOAYFWKG-UHFFFAOYSA-N

Vous recherchez des produits similaires ? Visite Guide de comparaison des produits

Description générale

Application

Mention d'avertissement

Warning

Mentions de danger

Conseils de prudence

Classification des risques

Carc. 2 - Eye Irrit. 2 - STOT SE 3

Organes cibles

Respiratory system

Code de la classe de stockage

11 - Combustible Solids

Classe de danger pour l'eau (WGK)

WGK 1

Point d'éclair (°F)

Not applicable

Point d'éclair (°C)

Not applicable

Équipement de protection individuelle

dust mask type N95 (US), Eyeshields, Faceshields, Gloves

Certificats d'analyse (COA)

Recherchez un Certificats d'analyse (COA) en saisissant le numéro de lot du produit. Les numéros de lot figurent sur l'étiquette du produit après les mots "Lot" ou "Batch".

Déjà en possession de ce produit ?

Retrouvez la documentation relative aux produits que vous avez récemment achetés dans la Bibliothèque de documents.

Les clients ont également consulté

Articles

Advances in materials have often been led by the development of new synthetic methods that provide control over size, morphology and structure.

Advances in materials have often been led by the development of new synthetic methods that provide control over size, morphology and structure. The preparation of materials in a scalable and continuous manner is critical when development moves beyond lab-scale quantities.

The production of hydrogen by catalytic water splitting is important for a wide range of industries including renewable energy petroleum refining and for the production of methanol and ammonia in the chemical industry.

Professor Chen (Nankai University, China) and his team explain the strategies behind their recent record-breaking organic solar cells, reaching a power conversion efficiency of 17.3%.

Notre équipe de scientifiques dispose d'une expérience dans tous les secteurs de la recherche, notamment en sciences de la vie, science des matériaux, synthèse chimique, chromatographie, analyse et dans de nombreux autres domaines..

Contacter notre Service technique