1.17328

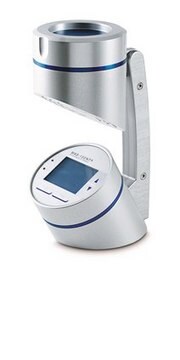

MAS-100 Atmos® Microbial Compressed Gas Sampler

For Compressed Gas Sampling

About This Item

Recommended Products

material

polystyrene housing

reg. compliance

FDA

product line

MAS-100®

feature

portable

manufacturer/tradename

MAS-100 Atmos®

greener alternative product characteristics

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

application(s)

compressed gas monitoring

cosmetics

food and beverages

pharmaceutical

compatibility

for use with 90 mm Petri Dishes

greener alternative category

General description

Like all MAS-100® microbial air samplers, the equipment principle is based on sieve impaction. The impaction of microorganisms takes place under pressure to prevent any harm to microorganisms caused by fast dynamic decompression.

A specific amount of compressed gas gets aspirated through a perforated lid (300*0.6mm) which captures the available microbes onto the surface of an agar plate (90-100mm pertridish) with an impaction speed of 19.7m/s.

The state-of-art design provides a nominal d50 value of 1.1 μm at a default flow rate of 100 liter/min (LPM).

An optional perforated lid with 300x0.47mm holes can be used for pre-selected flow rates of 50 LPM to achieve the same d50.

The system measures the current pressure, indicated either in bar abs. or Psi (1.2 to 7 bar abs. = 17.4 to 101.5 Psi), and regulates the flow rate based on a mass-flow sensor for each pre-selected gas type to 100 LPM. In case of low flow provided by the gas pipe, the instrument can automatically switch to 50 LPM. The decompression after sampling is performed automatically.

Data Integrity:

The MAS-100 Atmos® offers various operation modes for different workflow scenarios configurable via browser-based user interface:

- Freely accessible configuration by any operator (out of the box)

- 21 CFR Part 11 compliant management.

- Manage connected bar code reader.

- 2 D bar code including all sample data supports wireless transfer into EM software systems

A full audit trail including e-signatures as well as sample reports and error logs are available for download.

Individual configurable hardware keys combined with a PIN code allow 21 CFR Part 11 compliant login including defined access rights the selected user role as well as traceability.

The touch screen is used for operation and to display important information, such as current pressure (units selectable in bar abs. or Psi), battery status, date and time, sampling status and result data as a 2D bar code. A graphical user guide can be selected for easy instructions of workflow steps.

The MAS-100 Atmos® is powered by a Lithium-ion rechargeable battery that assures long battery life without routine discharging.

Application

Features and Benefits

- Easy to handle including graphical user guide on touch screen.

- Fully automated flow regulation per gas type by a mass flow sensor and pressure sensor.

- Fully automated decompression cycle.

- Software fully integrated in instrument and manageable via various web-browsers with internet connection.

- 21 CFR Part 11 compliant user management.

- Individual hardware key for login.

- Sample Data as barcode on touch screen for wireless integration into EM software programs using barcode readers.

- Impaction under pressure to reduces the risk of false negative results.

Components

- 1 x MAS-100 Atmos® microbial compressed gas sampler.

- 1 x Perforated lid 300x0.6mm.

- 1 x Dust Cover.

- 1 x Pressure connection tube; 2m PTFE; including 3/8′′ BSP female connector.

- 1 x Mini Trip-clamp (Ø 34 mm)

- 1 x Silicone gasket.

- 1 x Battery Charger including USB-C cable and country specific plug adapters.

- Documentation: Quick-start guide, declaration of conformity and calibration certificates (MAS-100 Atmos and calibration tool)

Other Notes

1.Insert the appropriate agar plate and select sample parameter (gas type, volume)

2.Connect the instrument to the gas outlet (PTFE pressure connection tube is provided with a 3/8′′BSP female adapter)

3.Open the gas valve and start sampling.

4.After sampling close the valve and start decompression.

5.Remove the plate.

6.Incubate the plate and count the colonies.

7.Correct CFU number according Feller table.

8.Calculate CFU/m3 (1000 Liter).

Contamination or intoxication of the sampling environment can be prevented mounting the optional exhaust tubing.

Legal Information

accessory

related product

Storage Class Code

11 - Combustible Solids

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Related Content

Our active microbial air samplers generate accurate and reproducible results for effective use in pharmaceutical, medical device, food and beverage industries where regulations are on the rise, and standards become increasingly stringent.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service