GRTRANSFER25

Graphene, monolayer film

Easy transfer, L × W 1 in. × 1 in.

About This Item

Recommended Products

Product Name

Easy transfer monolayer Graphene, L × W 1 in. × 1 in., avg. no. of layers, 1

feature

avg. no. of layers 1

growth mode

CVD

sheet resistance

450 +/- 40 Ω/sq, on SiO2/Si (1cm x 1cm)

L × W

1 in. × 1 in.

surface coverage

>98%

color

transparent>97%

grain size

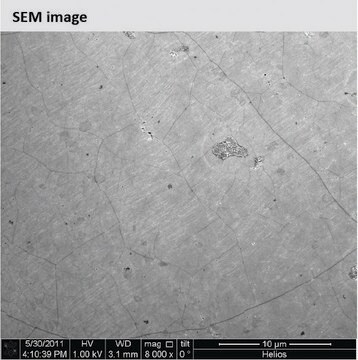

≤20 μm

Looking for similar products? Visit Product Comparison Guide

Related Categories

General description

Structure of the easy-transfer graphene:

Top sacrificial layer (square shaped), CVD monolayer graphene in the middle, and bottom water-releasable polymer support layer (round shaped)

Application

This product employs a specially designed mechanism for easy and clean transfer of high quality monolayer CVD grown graphene to build state-of-art electronic devices such as:

- Graphene based state-of-art FET

- Graphene based sensors

- Heterostructure based micro/nano electronics

Clean tranfer can be done following below 3 easy steps:

Release

Put the sample on deionized(DI) water slowly, round side (polymer layer) facing down, the square-shaped sacrificial layer+graphene will gradually detach from the rorund polymer film. Once the sacrificial layer/graphene is floating remove the round polymer film.

Transfer

Bring the desired substrate into the same DI water container while the sacrificial layer/graphene is floating. Tilt the substrate 45º and bring it into contact with the sacrificial layer/graphene from below. Take the sacrificial layer/graphene/substrate out and let it dry for 30 minutes in air. Then anneal the samples on a hot plate at 150 Celsius for 1h. Finally, before removing the sacrificial layer, store it under vacuum for at least 24h to avoid detachment of the graphene from your substrate.

Sacrificial layer Removal

To remove the sacrificial layer two methods can be used:

Solvents: Dip the sacrificial layer/graphene/substrate in acetone for 1h, then into isopropyl alcohol for another 1h and blow the sample with N2 to dry it.

Thermal treatment: Put the sacrificial layer/graphene/substrate into an oven and heat the sample at 450 C in

inert atmosphere for 2h.

Storage Class Code

11 - Combustible Solids

WGK

WGK 1

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Choose from one of the most recent versions:

Certificates of Analysis (COA)

It looks like we've run into a problem, but you can still download Certificates of Analysis from our Documents section.

If you need assistance, please contact Customer Support.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Articles

Dr. Xiang’s and Maruyama’s review presents the most recent research activities on 1D vdWHs, including the candidate materials, the synthetic techniques, and characterization methods. The optoelectronic applications are discussed in detail for different constructions of the 1D vdWHs-based devices (FETs, sensors, LEDs, photovoltaic devices, and light detection). Some challenges and perspectives for future development and applications of 1D vdWHs are also proposed to conclude the review.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service