736465

Silver, dispersion

nanoparticle, 30-35 wt. % in triethylene glycol monoethyl ether, spec. resistivity 11 μΩ-cm, for printing on plastic films

Synonym(s):

Silverjet DGP-40LT-15C, silver ink

About This Item

Recommended Products

Quality Level

description

surface tension 35 - 40 dyn/cm

form

dispersion

nanoparticle

concentration

30-35 wt. % in triethylene glycol monoethyl ether

refractive index

n20/D 1.333

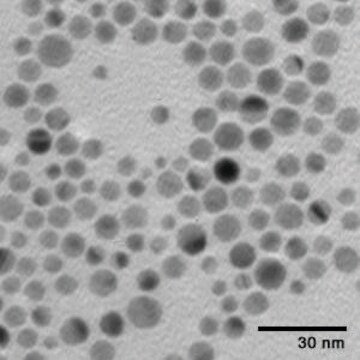

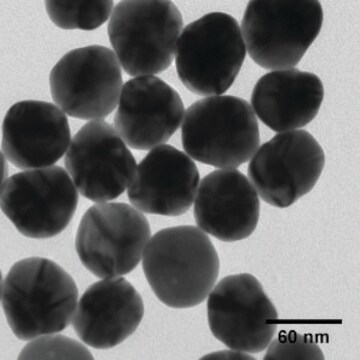

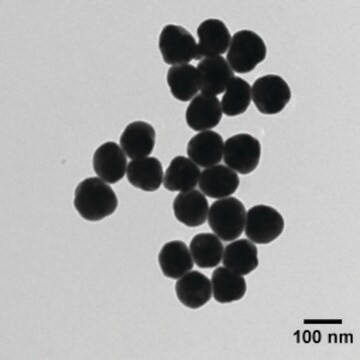

particle size

≤50 nm

viscosity

10-18 cP

density

1.45 g/mL±0.05 g/mL at 25 °C

storage temp.

2-8°C

SMILES string

[Ag]

InChI

1S/Ag

InChI key

BQCADISMDOOEFD-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

General description

Curing Temperature: 100-150 °C

Recommended substrates: Plastic films

Recommended washing solvent: Polar Solvents: Ethyl Alcohol, IPA etc.

Application

- Enhanced Adsorption of Trace Ethylene on Ag/NZ5 Modified with Ammonia: Hierarchical Structure and Metal Dispersion Effects.: This study examines the effects of hierarchical structure and metal dispersion in enhancing the adsorption of trace ethylene using silver/nanozeolite 5 modified with ammonia, exploring potential industrial applications for improved air quality and storage conditions (Qi et al., 2024).

- Structure-Activity Relationships between the State of Silver on Different Supports and Their I(2) and CH(3)I Adsorption Properties.: The paper details the correlation between the physical state of silver dispersed on various supports and its properties in adsorbing iodine and methyl iodide, which could be crucial for developing better filtration and purification systems (Azambre et al., 2021).

- New Relevant Descriptor of Linear QNAR Models for Toxicity Assessment of Silver Nanoparticles.: This publication introduces a new quantitative nanostructure-activity relationship (QNAR) descriptor that enhances the toxicity assessment of silver nanoparticles, significant for pharmaceutical applications where safety is paramount (Kudrinskiy et al., 2020).

- Resolving the puzzle of single-atom silver dispersion on nanosized γ-Al(2)O(3) surface for high catalytic performance.: Investigates the single-atom dispersion of silver on nano-sized γ-alumina surfaces, providing insights into optimizing the catalytic efficiency and potential applications in various chemical industries (Wang et al., 2020).

Analysis Note

Legal Information

Signal Word

Warning

Hazard Statements

Precautionary Statements

Hazard Classifications

Aquatic Acute 1 - Aquatic Chronic 1

Storage Class Code

10 - Combustible liquids

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

In the past decade, the family of digital printing technologies has evolved from being just a tool to visualize information into a generator of functionalities.

The emerging field of printed electronics requires a suite of functional materials for applications including flexible and large-area displays, radio frequency identification tags, portable energy harvesting and storage, biomedical and environmental sensor arrays,5,6 and logic circuits.

The ability to pattern conductive electrodes is technologically relevant for several applications, including photovolatics, displays, sensors, and biomedical devices.

Dr. Chan and researchers highlight flexible transistors are the building blocks of next-generation soft electronics. Among all the reported material systems that can be fabricated by researchers, such as circuits, biosensors, stretchable displays, and others,1–5 small molecular weight organic semiconductors are among the most promising candidates for flexible transistor applications. For these small molecular weight organic semiconductors, the semiconductor forming the conductive channel dominates the device performance.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service