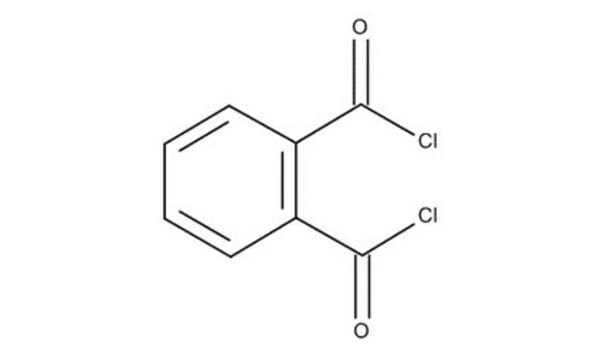

120871

Terephthaloyl chloride

≥99%, flakes

Synonym(s):

Terephthalic acid chloride, Terephthaloyl dichloride

About This Item

Recommended Products

vapor density

7 (vs air)

Quality Level

vapor pressure

0.02 mmHg ( 25 °C)

Assay

≥99%

form

flakes

bp

266 °C (lit.)

mp

79-81 °C (lit.)

solubility

ethanol: soluble 100 mg/mL, clear, colorless

functional group

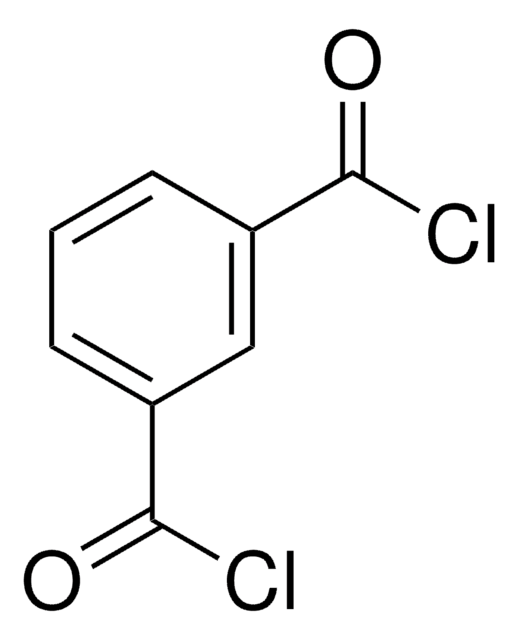

acyl chloride

SMILES string

ClC(=O)c1ccc(cc1)C(Cl)=O

InChI

1S/C8H4Cl2O2/c9-7(11)5-1-2-6(4-3-5)8(10)12/h1-4H

InChI key

LXEJRKJRKIFVNY-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

Related Categories

General description

Application

Legal Information

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Acute Tox. 3 Inhalation - Eye Dam. 1 - Skin Corr. 1A - STOT SE 3

Target Organs

Respiratory system

Storage Class Code

6.1A - Combustible acute toxic Cat. 1 and 2 / very toxic hazardous materials

WGK

WGK 1

Flash Point(F)

356.0 °F - closed cup

Flash Point(C)

180 °C - closed cup

Personal Protective Equipment

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Atomic layer deposition (ALD) techniques have emerged in the last ten years to meet various needs including semiconductor device miniaturization, conformal deposition on porous structures and coating of nanoparticles. ALD is based on two sequential self-limiting surface reactions.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service