735167

Fluorine doped tin oxide coated glass slide

L × W × thickness 300 mm × 300 mm × 2.2 mm, surface resistivity ~7 Ω/sq

Synonym(s):

FTO glass

About This Item

Recommended Products

description

Haze: 5%

composition

SnO2/F

surface resistivity

~7 Ω/sq

L × W × thickness

300 mm × 300 mm × 2.2 mm

transmittance

80-82% (visible)

Looking for similar products? Visit Product Comparison Guide

Related Categories

General description

Application

Storage Class Code

13 - Non Combustible Solids

WGK

WGK 2

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Organic photovoltaics (OPVs) represent a low-cost, lightweight, and scalable alternative to conventional solar cells. While significant progress has been made in the development of conventional bulk heterojunction cells, new approaches are required to achieve the performance and stability necessary to enable commercially successful OPVs.

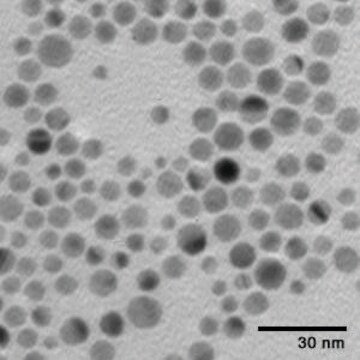

A transparent conductive electrode (TCE) is an essential component of various optoelectronic devices such as solar cells, liquid-crystal displays (LCD), light-emitting diodes (LED), and touch screens.

Next generation solar cells have the potential to achieve conversion efficiencies beyond the Shockley-Queisser (S-Q) limit while also significantly lowering production costs.

Professor Chen (Nankai University, China) and his team explain the strategies behind their recent record-breaking organic solar cells, reaching a power conversion efficiency of 17.3%.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service