767549

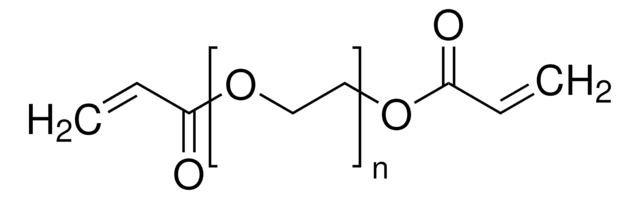

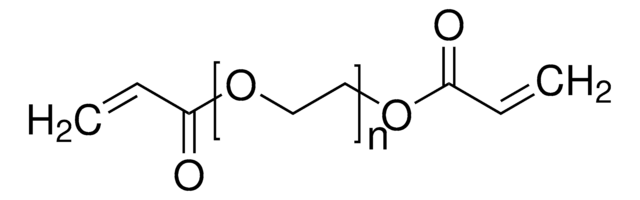

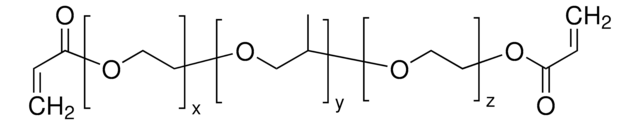

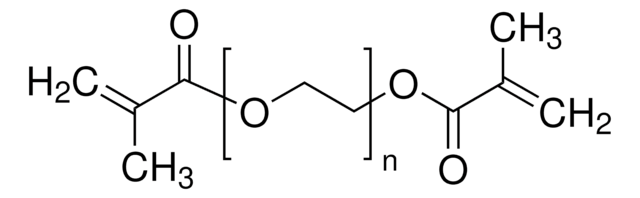

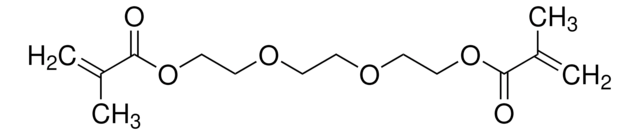

Poly(ethylene glycol) diacrylate

average Mn 20,000, PEG average Mn 20,000 (n~450), acrylate, ≤1000 ppm MEHQ as inhibitor

Sinónimos:

PEG diacrylate, Polyethylene glycol

About This Item

Productos recomendados

Nombre del producto

Poly(ethylene glycol) diacrylate, average Mn 20,000, contains ≤1000 ppm MEHQ as inhibitor

Formulario

solid

Nivel de calidad

mol peso

PEG average Mn 20,000 (n~450)

average Mn 20,000

contiene

≤1000 ppm MEHQ as inhibitor

idoneidad de la reacción

reagent type: cross-linking reagent

reaction type: Polymerization Reactions

mp

60-65 °C

Ω-final

acrylate

α-final

acrylate

arquitectura del polímero

shape: linear

functionality: homobifunctional

temp. de almacenamiento

−20°C

Categorías relacionadas

Descripción general

Aplicación

Palabra de señalización

Danger

Frases de peligro

Consejos de prudencia

Clasificaciones de peligro

Eye Dam. 1 - Skin Irrit. 2 - Skin Sens. 1

Código de clase de almacenamiento

11 - Combustible Solids

Clase de riesgo para el agua (WGK)

WGK 1

Punto de inflamabilidad (°F)

Not applicable

Punto de inflamabilidad (°C)

Not applicable

Elija entre una de las versiones más recientes:

Certificados de análisis (COA)

¿No ve la versión correcta?

Si necesita una versión concreta, puede buscar un certificado específico por el número de lote.

¿Ya tiene este producto?

Encuentre la documentación para los productos que ha comprado recientemente en la Biblioteca de documentos.

Los clientes también vieron

Artículos

Professor Shrike Zhang (Harvard Medical School, USA) discusses advances in 3D-bioprinted tissue models for in vitro drug testing, reviews bioink selections, and provides application examples of 3D bioprinting in tissue model biofabrication.

Professor Shrike Zhang (Harvard Medical School, USA) discusses advances in 3D-bioprinted tissue models for in vitro drug testing, reviews bioink selections, and provides application examples of 3D bioprinting in tissue model biofabrication.

In the past two decades, tissue engineering and regenerative medicine have become important interdisciplinary fields that span biology, chemistry, engineering, and medicine.

Devising biomaterial scaffolds that are capable of recapitulating critical aspects of the complex extracellular nature of living tissues in a threedimensional (3D) fashion is a challenging requirement in the field of tissue engineering and regenerative medicine.

Nuestro equipo de científicos tiene experiencia en todas las áreas de investigación: Ciencias de la vida, Ciencia de los materiales, Síntesis química, Cromatografía, Analítica y muchas otras.

Póngase en contacto con el Servicio técnico