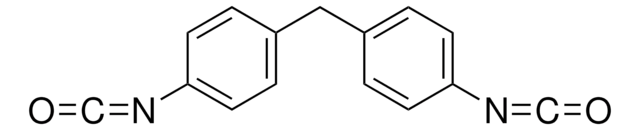

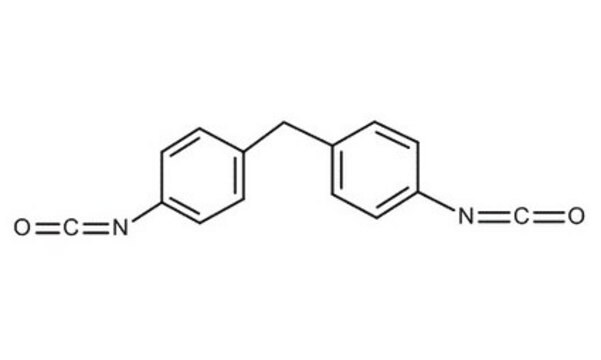

256439

4,4′-Methylenebis(phenyl isocyanate)

98%

Sinónimos:

4,4′-MDI, Bis(4-isocyanatophenyl)methane

About This Item

Productos recomendados

Nivel de calidad

Ensayo

98%

Formulario

solid

idoneidad de la reacción

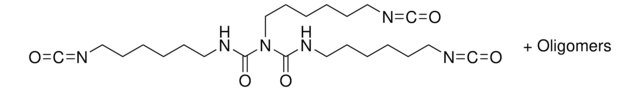

reagent type: cross-linking reagent

bp

200 °C/5 mmHg (lit.)

mp

42-45 °C (lit.)

densidad

1.18 g/mL at 25 °C (lit.)

temp. de almacenamiento

−20°C

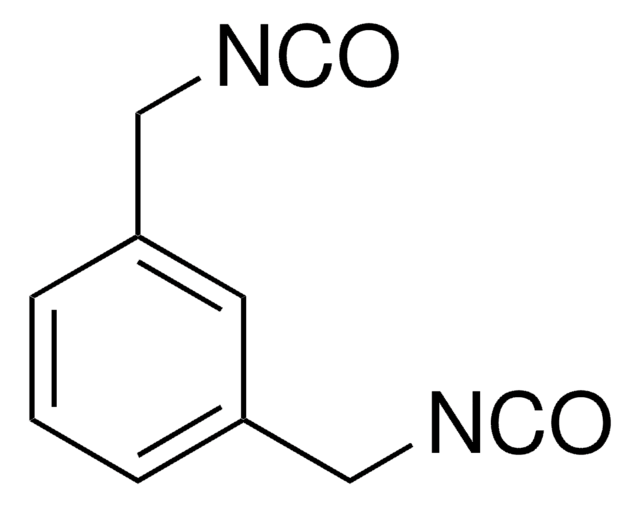

cadena SMILES

O=C=Nc1ccc(Cc2ccc(cc2)N=C=O)cc1

InChI

1S/C15H10N2O2/c18-10-16-14-5-1-12(2-6-14)9-13-3-7-15(8-4-13)17-11-19/h1-8H,9H2

Clave InChI

UPMLOUAZCHDJJD-UHFFFAOYSA-N

¿Está buscando productos similares? Visita Guía de comparación de productos

Categorías relacionadas

Descripción general

Aplicación

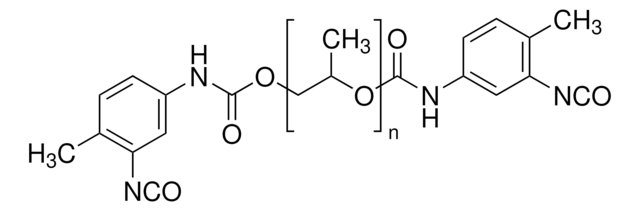

- Polyurethane cationomers, that are applicable in medical implants.

- A prepolymer for preparing self-healable polyurethane elastomers.

Palabra de señalización

Danger

Frases de peligro

Consejos de prudencia

Clasificaciones de peligro

Acute Tox. 4 Inhalation - Carc. 2 - Eye Irrit. 2 - Resp. Sens. 1 - Skin Irrit. 2 - Skin Sens. 1 - STOT RE 2 Inhalation - STOT SE 3

Órganos de actuación

Respiratory system

Código de clase de almacenamiento

11 - Combustible Solids

Clase de riesgo para el agua (WGK)

WGK 1

Punto de inflamabilidad (°F)

411.8 °F - closed cup

Punto de inflamabilidad (°C)

211 °C - closed cup

Equipo de protección personal

dust mask type N95 (US), Eyeshields, Faceshields, Gloves

Listados normativos

Los listados normativos se proporcionan para los productos químicos principalmente. Para los productos no químicos sólo se puede proporcionar información limitada. Si no hay ninguna entrada, significa que ninguno de los componentes está en la lista. Es obligación del usuario garantizar el uso seguro y legal del producto.

EU REACH Annex XVII (Restriction List)

Elija entre una de las versiones más recientes:

¿Ya tiene este producto?

Encuentre la documentación para los productos que ha comprado recientemente en la Biblioteca de documentos.

Los clientes también vieron

Global Trade Item Number

| Número de referencia del producto (SKU) | GTIN |

|---|---|

| 256439-10KG | |

| 256439-500G | 4061826058138 |

| 256439-50G | 4061826058145 |

| 256439-5KG | 4061833605783 |

Nuestro equipo de científicos tiene experiencia en todas las áreas de investigación: Ciencias de la vida, Ciencia de los materiales, Síntesis química, Cromatografía, Analítica y muchas otras.

Póngase en contacto con el Servicio técnico