809942

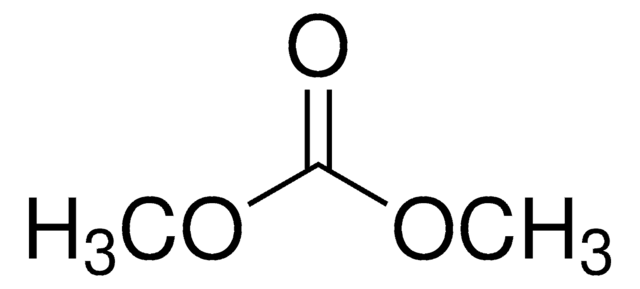

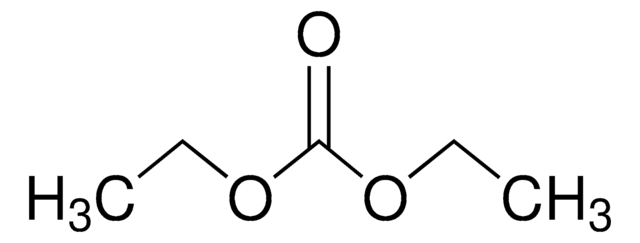

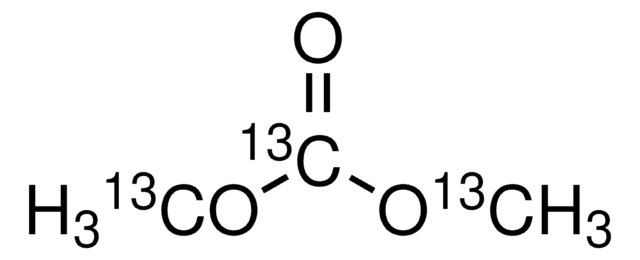

Dimethyl carbonate

battery grade, ≥99.9%, acid <10 ppm, H2O <10 ppm

Synonym(s):

DMC, dimethyl ester, Carbonic acid dimethyl ester

About This Item

Recommended Products

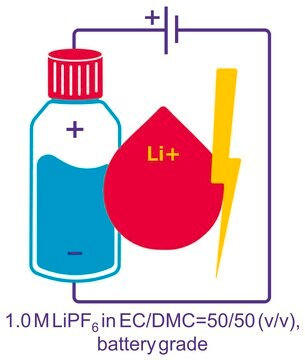

grade

battery grade

Quality Level

vapor density

3.1 (vs air)

vapor pressure

18 mmHg ( 21.1 °C)

Assay

≥99.9%

form

liquid

greener alternative product characteristics

Less Hazardous Chemical Syntheses

Safer Solvents and Auxiliaries

Design for Degradation

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

impurities

≤10 ppm H2O

≤10 ppm acid

refractive index

n20/D 1.368 (lit.)

bp

90 °C (lit.)

mp

2-4 °C (lit.)

density

1.069 g/mL at 25 °C (lit.)

application(s)

battery manufacturing

greener alternative category

, Aligned

SMILES string

O=C(OC)OC

InChI

1S/C3H6O3/c1-5-3(4)6-2/h1-2H3

InChI key

IEJIGPNLZYLLBP-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

General description

Application

Other Notes

- These additives have low water content (less than 100 ppm).

- Please handle under inert and moisture free environment (glove box).

- Keep containers tightly closed.

- Keep away from heat and ignition sources.

- Store in a cool and dry place.

- Avoid storing together with oxidizers.

Legal Information

related product

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Flam. Liq. 2

Storage Class Code

3 - Flammable liquids

WGK

WGK 1

Flash Point(F)

60.8 °F - closed cup

Flash Point(C)

16 °C - closed cup

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Don't see the Right Version?

If you require a particular version, you can look up a specific certificate by the Lot or Batch number.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

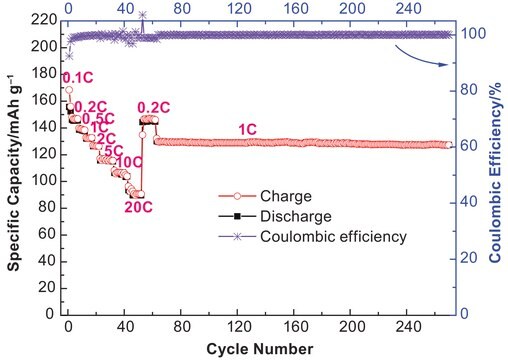

Dr. Schmuch, Dr. Siozios, Professor Dr. Winter, and Dr. Placke review the challenges and opportunities of nickelrich layered oxide cathode materials. They discuss production processes for the layered oxide cathode materials as well as their chemistry and morphology.

Due to the adverse impact of the continued use of fossil fuels on the earth’s environment and climate, researchers have been asked to develop new approaches for producing power using renewable sources like wind and solar energy

Here, we present a short review of ionic liquid electrolytes used in state-of-the-art rechargeable batteries including high performance and low-cost aluminum batteries, non-flammable Li-based batteries, and high-cycling and stable dual-graphite batteries. We also outline the key issues explored so as to identify the future direction of IL development.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service