918571

3D Printable Yttria-stabilized Zirconium(IV) Oxide Ink

Synonym(e):

3D printable ceramic ink, 3Y-ZrO2 ink, YSZ ink, Yttria stabilized zirconia ink, Yttrium stabilized zirconium oxide ink

About This Item

Empfohlene Produkte

Beschreibung

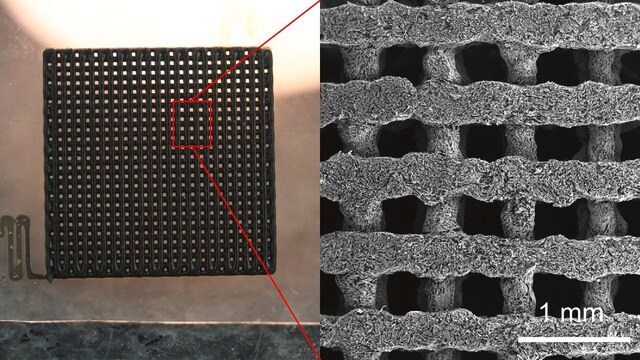

Printing methods compatible with: Direct-Ink-Writing 3D printing

Qualitätsniveau

Form

paste

Grünere Alternativprodukt-Eigenschaften

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

Konzentration

70 wt. % (Yttria stabilized zirconia)

Farbe

white

Partikelgröße

120 nm

Viskosität

2-25 Pa.s (25 °C at shear rate of 100 s-1)

Grünere Alternativprodukt-Kategorie

Lagertemp.

2-8°C

Allgemeine Beschreibung

Anwendung

Vorsicht

- Store in an airtight sealed container in refrigerator.

- Avoid exposure to heat.

- Add the thermal initiator (product No.479896) to 0.3wt% of the total 3Y-ZrO2/PEGDA ink mass, and mix well before usage.

Angaben zur Herstellung

Direct-Ink-Writing (DIW) Notes:

- Syringe Nozzle sizes ranging from 250 μm − 800 μm can be used.

- Initial pressure for DIW printing ranges from 12-18 psi, depending on nozzle diameter used.

Post Processing of DIW printed parts:

- Curing @ 110°C for 12-16 hours.

- Sintering using the following sequence:

Ramp to 300°C @ 1°C/min. Hold for 4 hours.

Ramp to 400°C @ 1°C/min. Hold for 2 hours.

Ramp to 800°C @ 2°C/min. Hold for 4 hours.

Ramp to 1090°C @ 2°C/min. Hold for 15 hours.

Ramp down to 50°C @ 2°C/min.

Lagerung und Haltbarkeit

Signalwort

Danger

H-Sätze

Gefahreneinstufungen

Eye Dam. 1 - Skin Irrit. 2 - Skin Sens. 1 - STOT SE 3

Zielorgane

Respiratory system

Lagerklassenschlüssel

10 - Combustible liquids

WGK

WGK 3

Hier finden Sie alle aktuellen Versionen:

Analysenzertifikate (COA)

Leider sind derzeit keine COAs für dieses Produkt online verfügbar.

Wenn Sie Hilfe benötigen, wenden Sie sich bitte an Kundensupport

Besitzen Sie dieses Produkt bereits?

In der Dokumentenbibliothek finden Sie die Dokumentation zu den Produkten, die Sie kürzlich erworben haben.

Unser Team von Wissenschaftlern verfügt über Erfahrung in allen Forschungsbereichen einschließlich Life Science, Materialwissenschaften, chemischer Synthese, Chromatographie, Analytik und vielen mehr..

Setzen Sie sich mit dem technischen Dienst in Verbindung.