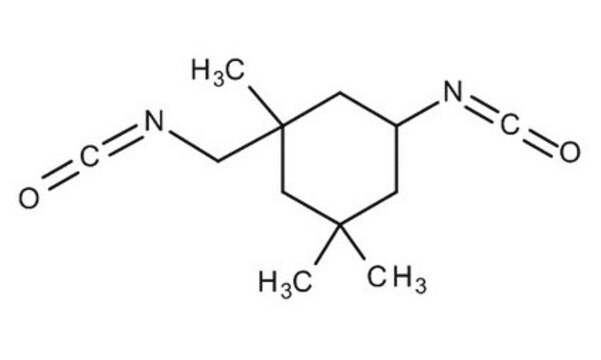

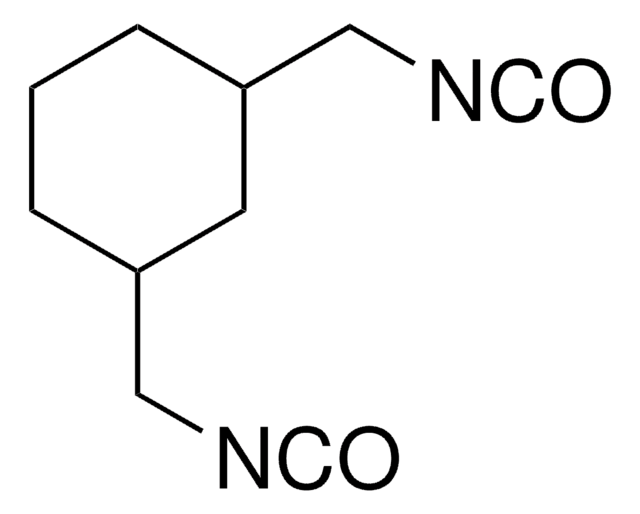

317624

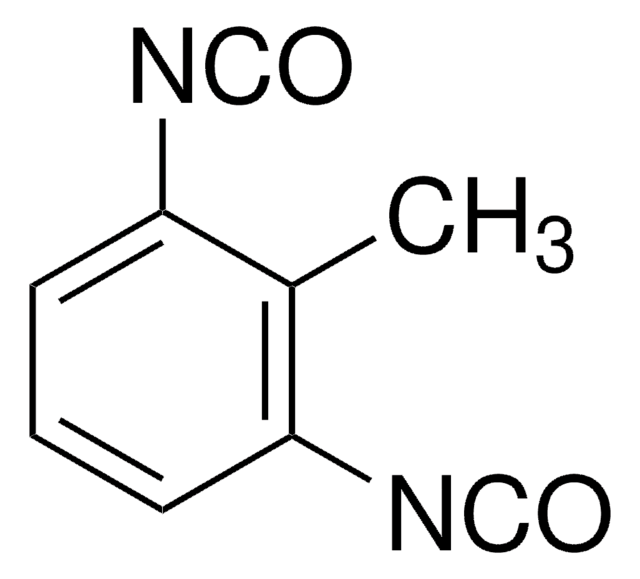

Isophorone diisocyanate

98%, mixture of isomers

Synonyme(s) :

5-Isocyanato-1-(isocyanatomethyl)-1,3,3-trimethylcyclohexane

About This Item

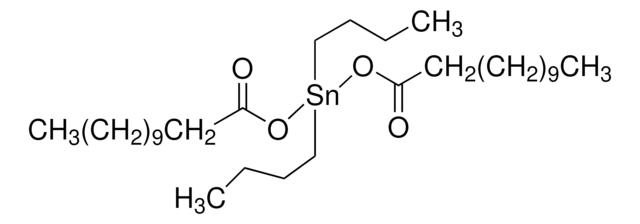

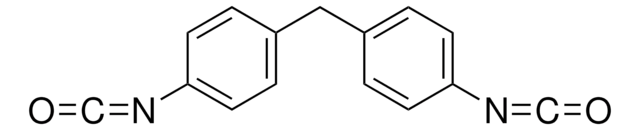

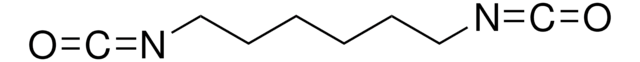

Produits recommandés

Niveau de qualité

Pureté

98%

Forme

liquid

Indice de réfraction

n20/D 1.484 (lit.)

Point d'ébullition

158-159 °C/15 mmHg (lit.)

Densité

1.049 g/mL at 25 °C (lit.)

Chaîne SMILES

CC1(C)CC(CC(C)(CN=C=O)C1)N=C=O

InChI

1S/C12H18N2O2/c1-11(2)4-10(14-9-16)5-12(3,6-11)7-13-8-15/h10H,4-7H2,1-3H3

Clé InChI

NIMLQBUJDJZYEJ-UHFFFAOYSA-N

Vous recherchez des produits similaires ? Visite Guide de comparaison des produits

Description générale

Application

- Production of polyurethane coatings for automotive and industrial applications.

- Synthesis of polyurethane elastomers used in medical devices and sports equipment.

- Production of polyurethane foams used in upholstery, insulation, and packaging applications.

- Use in the manufacture of adhesives, sealants, and binders.

- In the synthesis of bridged silsesquioxane(BSQ) by sol-gel polycondensation with 3-aminopropyltriethoxysilane. The polymer of BSQ can be used to prepare the moisture-resistant film for UV filters.

- As a healing agent in the preparation of polyurethane microcapsules by interfacial polymerization.

- As a monomer in the synthesis of highly monodispersed polyurea microspheres via precipitation polymerization.

Mention d'avertissement

Danger

Mentions de danger

Conseils de prudence

Classification des risques

Acute Tox. 1 Inhalation - Aquatic Chronic 2 - Eye Irrit. 2 - Resp. Sens. 1 - Skin Irrit. 2 - Skin Sens. 1 - STOT SE 3

Organes cibles

Respiratory system

Code de la classe de stockage

6.1A - Combustible acute toxic Cat. 1 and 2 / very toxic hazardous materials

Classe de danger pour l'eau (WGK)

WGK 2

Point d'éclair (°F)

325.4 °F - closed cup

Point d'éclair (°C)

163 °C - closed cup

Équipement de protection individuelle

Eyeshields, Faceshields, Gloves, type ABEK (EN14387) respirator filter

Faites votre choix parmi les versions les plus récentes :

Déjà en possession de ce produit ?

Retrouvez la documentation relative aux produits que vous avez récemment achetés dans la Bibliothèque de documents.

Les clients ont également consulté

Protocoles

HPLC Analysis of Isocyanates on Titan™ C18

Notre équipe de scientifiques dispose d'une expérience dans tous les secteurs de la recherche, notamment en sciences de la vie, science des matériaux, synthèse chimique, chromatographie, analyse et dans de nombreux autres domaines..

Contacter notre Service technique