41474

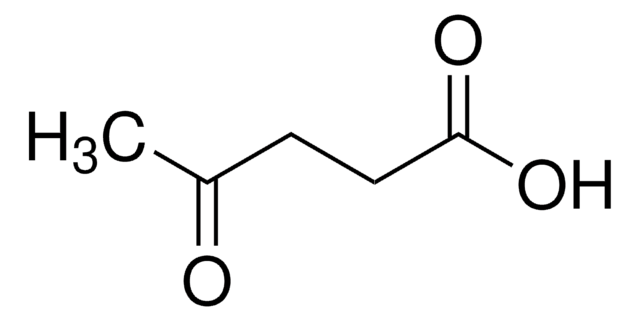

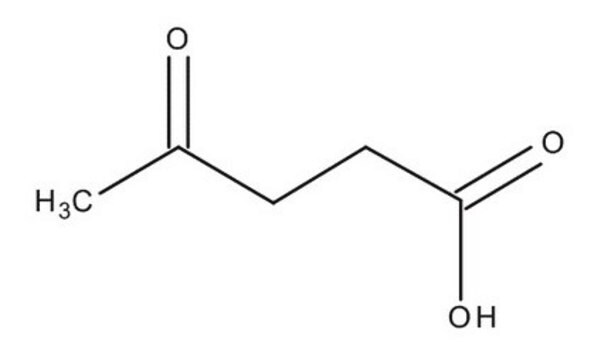

Levulinic acid

analytical standard

Synonym(s):

4-Oxopentanoic acid, 4-Oxovaleric acid

About This Item

Recommended Products

grade

analytical standard

Quality Level

vapor pressure

1 mmHg ( 102 °C)

Assay

≥97.5% (GC)

97.5-102.5% (T)

shelf life

limited shelf life, expiry date on the label

technique(s)

HPLC: suitable

gas chromatography (GC): suitable

bp

245-246 °C (lit.)

mp

30-33 °C (lit.)

density

1.134 g/mL at 25 °C (lit.)

application(s)

cleaning products

cosmetics

flavors and fragrances

food and beverages

personal care

format

neat

SMILES string

CC(=O)CCC(O)=O

InChI

1S/C5H8O3/c1-4(6)2-3-5(7)8/h2-3H2,1H3,(H,7,8)

InChI key

JOOXCMJARBKPKM-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

General description

Application

for the quantification of the analyte in the following:

- Soy sauce using liquid chromatography coupled to mass spectrometry (LC–MS).

- Liquid food samples using gas chromatography with flame ionization detection (GC-FID).

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Acute Tox. 4 Oral - Eye Dam. 1 - Skin Sens. 1

Storage Class Code

13 - Non Combustible Solids

WGK

WGK 2

Flash Point(F)

208.4 °F - closed cup

Flash Point(C)

98 °C - closed cup

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service