902403

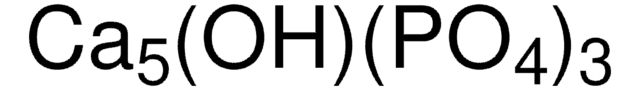

3D Printing Hydroxyapatite ink

Synonym(s):

3D printing Hydroxylapatite ink, Calcium phosphate hydroxide, Durapatite, Hydroxyapatite, Hydroxylapatite, Hyperelastic bone

About This Item

Recommended Products

form

liquid

greener alternative product characteristics

Design for Energy Efficiency

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

viscosity

20-60 Pa.s

greener alternative category

storage temp.

2-8°C

General description

Application

Our Hyper elastic Bone 3D-printing ink is comprised of micron sized hydroxyapatite suspended in a mixture of organic solvents containing a dissolved, high molecular weight elastomeric, biocompatible polyester (polylactic-co-glycolic acid;PLGA). Prior to further use, to remove residual solvents after 3D-printing (or other application such as coating, direct painting etc) the composite material should be washed in 70% ethanol and then by water. The 3D-printed hydroxyapatite can be used as a flexible, bioactive, biocompatible ceramic composite or it can also be sintered (1500 °C recommended) in a non-oxidative atmosphere to yield Hyper elastic Bone parts. As sintered, Hyper elastic Bone is highly chemically and thermally stable, and can be used for a wide variety of high temperature applications. It also has numerous hard biological tissue (teeth and bone) applications, and can serve in it as as-printed, washed form as flexible ceramic composite cell scaffold, or in its sintered form, as a rigid ceramic scaffold/implant. In its 3D-printed, flexible form, Hyper elastic Bone has been shown to be highly osteoconductive, and osteogenic, capable of differentiation adult human stem cells into osteoblast-like cells.

Caution

Signal Word

Danger

Hazard Statements

Precautionary Statements

Hazard Classifications

Aquatic Chronic 3 - Carc. 2 - Eye Irrit. 2 - Repr. 1B - Skin Irrit. 2 - STOT SE 3

Target Organs

Central nervous system

Storage Class Code

6.1C - Combustible acute toxic Cat.3 / toxic compounds or compounds which causing chronic effects

WGK

WGK 3

Flash Point(F)

152.6 °F

Flash Point(C)

67 °C

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Don't see the Right Version?

If you require a particular version, you can look up a specific certificate by the Lot or Batch number.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Bioinks selection guide for 3D bioprinting of cells for tissues engineering applications.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service