900741

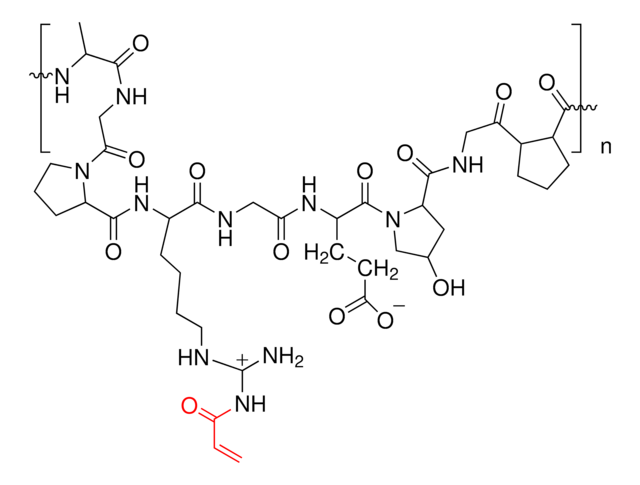

Gelatin methacryloyl

gel strength 170-195 g Bloom, degree of substitution: 60%

Synonym(s):

GelMA, Gelatin methacrylamide, Gelatin methacrylate, GelMa, Gelatin Methacrylate

About This Item

Recommended Products

Looking for similar products? Visit Product Comparison Guide

Related Categories

Application

Storage Class Code

11 - Combustible Solids

WGK

WGK 3

Flash Point(F)

Not applicable

Flash Point(C)

Not applicable

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Don't see the Right Version?

If you require a particular version, you can look up a specific certificate by the Lot or Batch number.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Professor Shrike Zhang (Harvard Medical School, USA) discusses advances in 3D-bioprinted tissue models for in vitro drug testing, reviews bioink selections, and provides application examples of 3D bioprinting in tissue model biofabrication.

Professor Shrike Zhang (Harvard Medical School, USA) discusses advances in 3D-bioprinted tissue models for in vitro drug testing, reviews bioink selections, and provides application examples of 3D bioprinting in tissue model biofabrication.

Related Content

Tissue engineering fabricates tissues cultures from scaffolds, living cells, and biologically active molecules by simulating the microenvironment of the body to repair or replace damaged tissue.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service